The Canadian Pacific Railway's Legendary Angus Shops

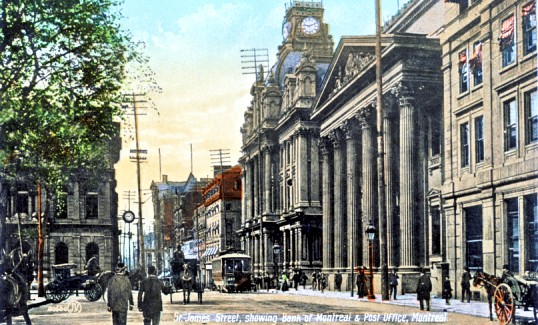

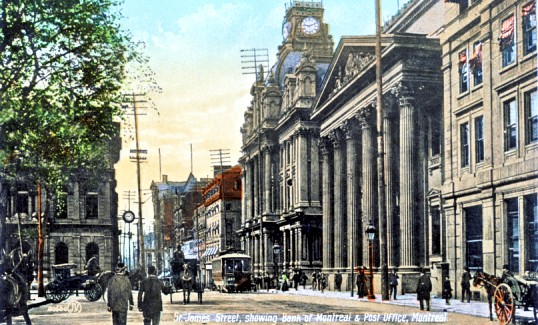

Richard Bladworth Angus was born in 1831 in Bathgate, Scotland - about

20 miles west of Edinburgh. He came to Canada at age 26 with his wife

and began work as a bookkeeper and clerk with the Bank of Montreal.

After a time working for B of M in America's First and Second Cities, he

became general manager at the headquarters of the bank at age 38 in 1869 - two years after

Canadian Confederation.

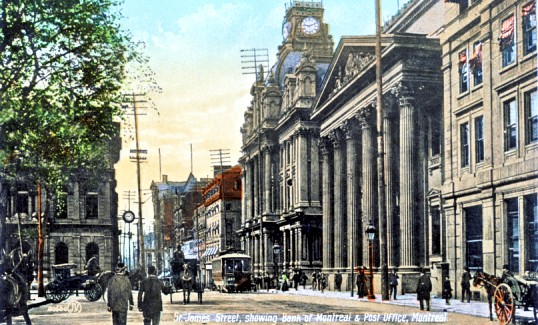

The building with the classic columns is the bank's head office.

The building with the classic columns is the bank's head office.

Angus then joined those famous Scottish cousins - George Stephen and Donald Smith - in

private investments.

Along the way, they met a Canadian who liked the challenge of building and running railways : J J Hill.

George Stephen also became president of the Bank of Montreal.

In a business world devoid of the complications of conflict of

interest laws, regulations, guidelines, aspirational targets, or sniff tests

...

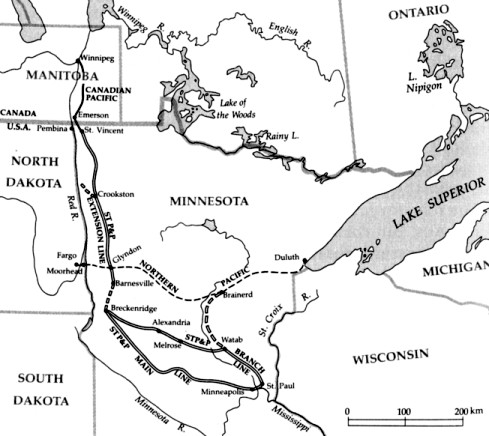

Stephen, Smith and some business partners bought the American St Paul and Pacific Railroad

in 1878. Some Montrealers wondered if Angus and Stephen could work in

Bank of Montreal's best interests while some of its funds were being privately used

by them and their associates to buy a bankrupt US railroad for over $5

million.

Angus subsequently resigned from the Bank of Montreal and became vice president of the renamed

road - the St Paul, Minneapolis and Manitoba Railroad - in 1879 ... the "Manitoba Road".

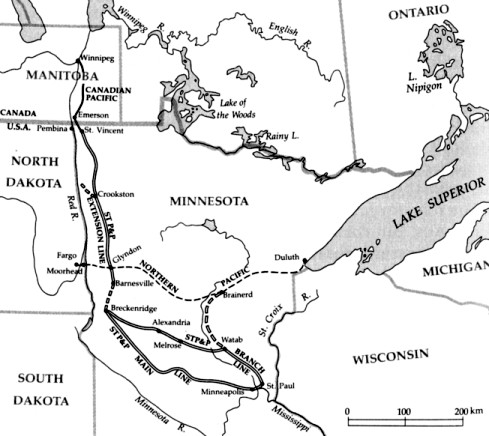

The Manitoba Road circa the 1880s

The Manitoba Road circa the 1880s

CPR construction feeder

Vice President & Co-investor : RB Angus

(Back then Winnipeg was in northern Manitoba!)

-

You already know that during CPR construction ... the Prairie and Rockies CPR

was separated from the Eastern CPR by the rolling sea of Precambrian granite

north of Lake Superior.

- The St PM&M - majority owned by the associates alluded to above (exact holdings not disclosed) connected ... the US midwestern rail network at the Twin Cities ... to a CPR feeder line ... which connected that point on the American border ... to Winnipeg.

The Point ...

Pretty much everything and everyone needed for construction of the

CPR out of Winnipeg ... came over the line controlled by Stephen,

Smith, Hill, Angus et al.

The Canadian legend is that if the CPR went bust, Stephen and Smith should be seen to be personally bankrupt, themselves.

The way things turned out, the Manitoba Line made Smith, Stephen and

their co-investors a small fortune - one of many good investments they

made.

But getting back to Angus ...

After his initial work with the associates at the Bank of Montreal, and on the Manitoba

Road,

Angus was involved in the following CPR and high-finance related

activities ...

- Provided financial analysis on a regular basis, complementing Stephen's entrepreneurial prowess ... for the CPR Syndicate ... and later for the CPR.

- Signed the Canadian Pacific Railway Contract with the government ... as one of the CPR Syndicate's original members.

- Worked as the first CPR General Manager until 1882 when Van Horne was hired.

- Spiked together the CPR's eastern network, particularly in the key Montreal, Ottawa, Toronto area..

- Served on the CPR board and committees for 40 years.

- Invested in Dominion Bridge of Lachine Quebec ... which supplied most of the heavy steel structures the CPR needed.

- Invested in Canadian industry : paper, telephones, hydro power & street railways, and sugar refining. Sweeet.

- Returned to the Bank of Montreal as President, serving 1910-1913.

- The new Canadian Pacific Railway Angus Shops complex was named after him when it opened in 1904.

- He died in 1922.

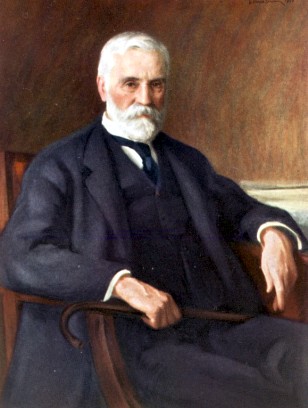

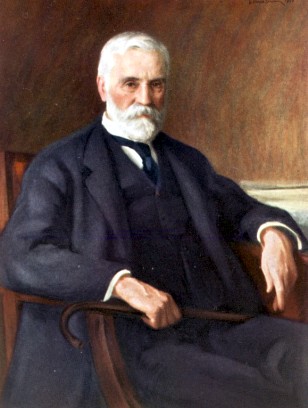

R.B. Angus

Angus Shops : Meeting the Needs of the Railway

and The Empire ! : "hurrah! hurrah! hurrah! ... and a tiger! ... grrrrr"

As mentioned elsewhere on this

website ... the CPR's various rolling stock shops - acquired from

absorbed eastern Canadian railways - combined with the CPR's own tiny,

perfect Delorimier Shops (the "New Shops") ... would not

provide the scale, efficiency, and standardization the CPR wanted.

Eight years after Angus Shops opened ... and a quarter of a century after the

last spike ... the following figures from the government's railway

statistics show that scale, efficiency, and standardization of rolling stock processes were essential for the CPR's operations.

CPR in 1912 : Equipment Costs

Equipment

Type

|

Repair ($)

|

Renewals

($)

|

Steam locomotives

|

5,375,518

|

167,374

|

Passenger cars

|

1,987,274

|

90,888

|

Freight cars

|

3,571,412

|

739,911

|

Work equipment

|

561,061

|

187,425

|

For perspective:

CPR transportation revenues 1912: $114,303,208

This is the financial

argument for Angus. Without beginning to consider buying new rolling

stock, maintaining tracks and roadbed, paying train crews, buying fuel,

or any of the other activities carried on all across Canada, the CPR was

spending a great deal of money keeping its equipment in good condition ... with Angus well-established.

Fun fact : the CPR was paying over $500,000 a year for water for its mainline steam locomotives !

I have fooled around with calculating inflation and perhaps multiplying

these numbers by 15-20 might give you an approximation in today's

dollars.

CPR in 1912 : Types of Rolling Stock on the Roster

Locomotives ...

|

1820

|

Passenger

|

516

|

Freight

|

1077

|

Switching

|

227

|

Passenger cars ...

|

2237

|

First Class

|

748

|

Second Class

|

174

|

Combination [e.g. passenger + baggage]

|

108

|

Emigrant [no frills sleeping/cooking]

|

315

|

Dining

|

96

|

Parlour

|

27

|

Sleeping

|

273

|

Baggage, Express, Postal

|

491

|

Other passenger

|

5

|

Freight cars ...

|

61,446

|

Box

|

43,552

|

Flat

|

7982

|

Stock [livestock]

|

3534

|

Coal

|

3351

|

Tank

|

178

|

Refrigerator

|

1501

|

Other freight

|

1348

|

On company service (OCS) cars...

|

5367

|

Officers & pay cars

|

45

|

Gravel

|

1470

|

Derrick

|

67

|

Caboose

|

1065

|

Other

|

2720

|

This is the organizational

argument

for Angus. A large, complex organization like the CPR needed to get

some control over all of these rolling 20 to 300 ton assets. Angus was

the "main

place" where standard plans, standard procedures, and new programs were

established. There were other, smaller shop complexes in western Canada

for geographical efficiency (Ogden at Calgary, Weston at Winnipeg),

but Angus was the focus of the CPR's attention when it came to rolling

stock.

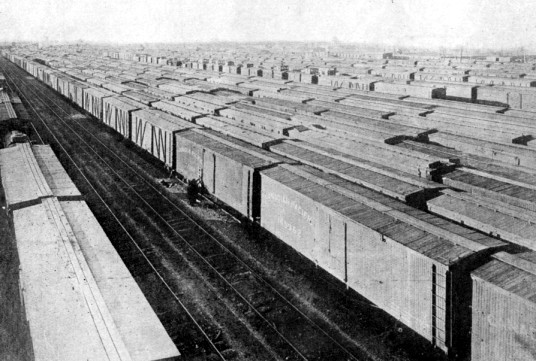

In a sea of wooden cars in the CPR yard at Winnipeg ... it looks as if some Plasma TV's are being pilfered !

This photograph from 1910 or so shows a nice variety of wooden cars ... all of which must be maintained.

... and meeting the needs of The Empire ...

Of course this was not foreseen when Angus was built ... but as World War One began a decade after Angus opened,

there was no CNR ...

The Grand Trunk lines, the Canadian Northern ... and other railways which

were already wards of the state, did not form an integrated

efficient system.

Given Canada's Empire-dictated participation in the

Great War ... and the quantity of railway assets and CPR staff eventually

needed in Europe ... it was fortunate that the CPR had its act together as

a

national railway, and that Angus was already well-established when the

war began. To some extent, Angus Shops also began producing war materiel - beginning with

artillery shells in 1915.

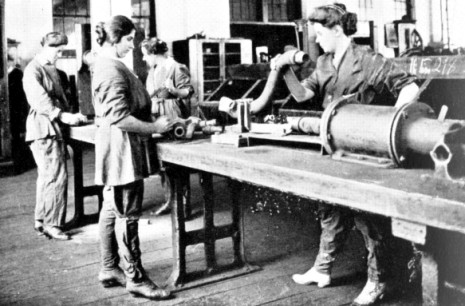

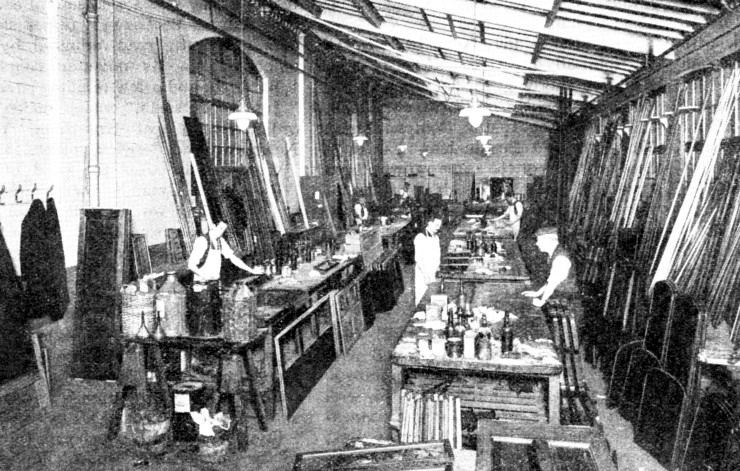

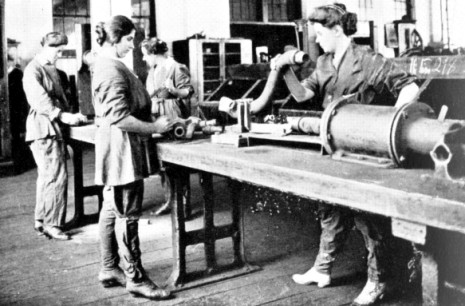

Clean air brake components are on the workbench ...

probably at a photogenic training area at Angus.

With the active recruitment of skilled CPR employees into World War One,

women are employed at Angus Shops ...

'til the boys come home ...

then the typical post-war female employee purge will occur.

Angus Shops : The Location

This 1915 map shows the location of Angus Shops in the east end of

Montreal. The blue lines represent streetcar tracks.

Before the

construction of Windsor Station to the west, the CPR's main Montreal

passenger station was at

Place Viger - beyond the lower left corner of this map. Leaving Viger

Station, a departing

passenger train would first pass the CPR's original shops (Delorimier)

... then the

car shop and roundhouse at Hochelaga (shown) ... before passing the

location of Angus Shops as it headed west. As you can see by the map,

it would make a horseshoe-shaped passage through eastern Montreal

before leaving Montreal Island.

The railway line shown heading to the east between Ernest and Ontario streets is that of the

Canadian Northern Railway. At the time, CNoR's Montreal station was at the foot of Moreau Street ... beside Hochelaga.

Ile Ronde is now forms the downstream tip of

the artificial islands created for Expo 67 from Montreal's subway tailings.

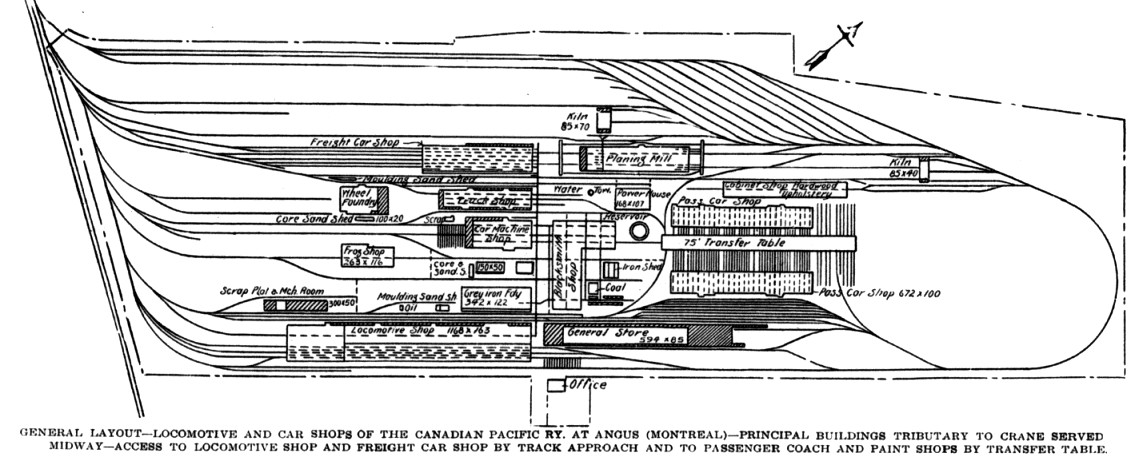

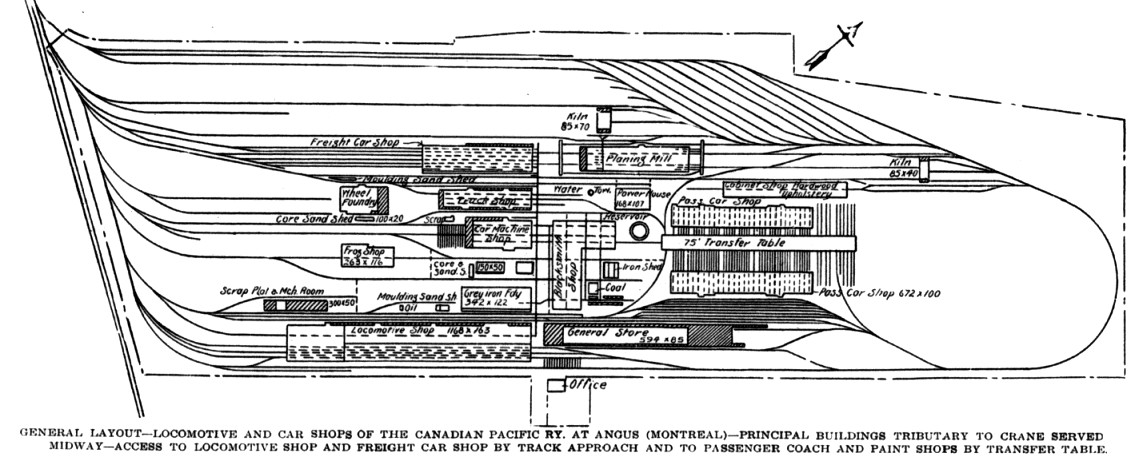

Angus Shops : The Layout in 1907

Below, you can see the main line along the left edge of this map. Here are a few of the main features from a 1907 map :

- The plot of land is about 1 mile long and 1/2 mile wide. It contains about 50 miles of track.

- The "midway" (yay, rides!) was an all-purpose through-way served

by high-capacity overhead crane(s). It appears here as the vertical passageway above the office.

- Freight cars were built and renewed at the top left corner. Below the freight car shop is the "truck shop" where the wheelsets were built and maintained.

- Passenger cars were built and renewed at the right side -

notice the 75 foot long transfer table ... whose pit marked on the map (the wide, white rectangle)

- The shop interior frequently shown in books is the locomotive shop at the lower left.

Some obscure points:

- Railway shops often used a transfer table as the central

transportation axis of the shops - i.e. at the midway. However, by

building at the Montreal city

limits, the CPR obtained enough land for a spacious layout.

Consequently, most rolling stock could travel normally (longitudinally) on rails

into the various shops - including the steam locomotives. You can see

the two

gentle curves giving access to the only transfer table in the place ...

at the passenger car shop. Why is this such a big deal? ... The

transfer table usually runs in a transfer table pit

which makes other surface movement across the pit difficult. With no huge "trench" running down the midway, the CPR was able to send

pedestrians, teams of horses pulling loads, and the overhead crane(s) down

the midway.

- In addition, a series of standard gauge rail-ways ran perpendicular

to the main rail axis of the complex, allowing pushcarts of materials or components to

roll from building to building. To turn the railed loads 90 degrees, 8 foot diameter

turntables were used at strategic locations.

- There was plenty of storage space for raw materials, parts inventory, and scrap management.

- Tributary shops were close to their "customers" ... e.g. wheel

foundry > freight car shop ; grey iron foundry > locomotive shop;

kiln > planing mill > cabinet shop > passenger car shop.

- The linear rolling stock shops usually worked on a "first

in, first out" basis with individual cars or locomotives moving along

in "assembly line" fashion.

- The frog shop at the centre left was used to build the specialized rail assemblies and other pieces used in switches, and railway-crossing-railway track "diamonds".

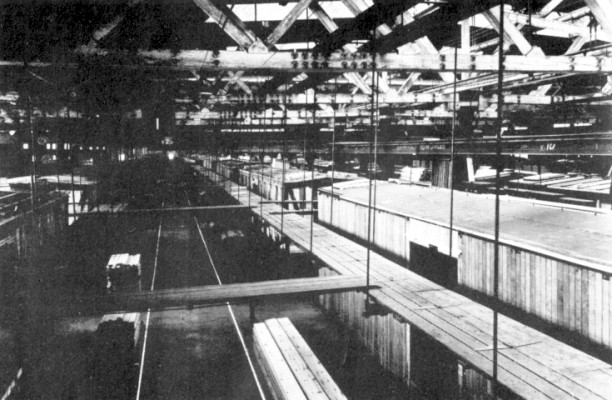

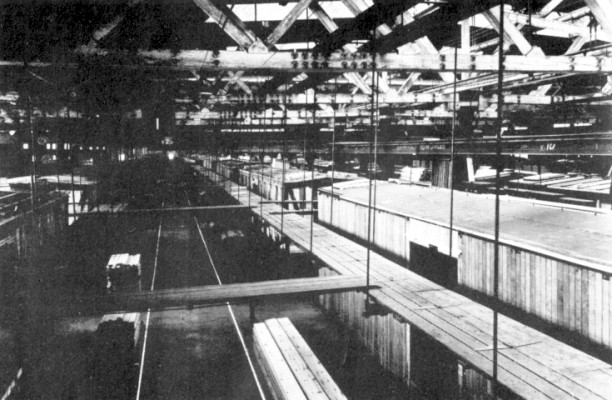

"Have you seen my pipe wrench? I left it under that car ... "

Taken in 1948 after extensive facility development, this photo shows the orderly but cluttered west end of Angus.

Taken in 1948 after extensive facility development, this photo shows the orderly but cluttered west end of Angus.

This is the car shop area and the midway and overhead crane track can be seen in the top right corner.

Inside Angus Shops

Angus

is best remembered for its locomotive building and rebuilding, so views

of other operations are generally not common.

Here are a few typical scenes in the car shops.

Shortly after World War Two, some cast steel wheels are being harvested at the wheel foundry.

At its peak, over 70,000 cast steel wheels were being produced annually at Angus.

This view is from earlier, probably around 1910 in the wooden car shop.

This view is from earlier, probably around 1910 in the wooden car shop.

Tidiness and fire protection were essential.

I guess they let people work when there were no cameras around.

At the passenger car works of the London and North Eastern Railway in England around 1930,

you can see the type of work done at Angus with passenger car interior wood.

For easier reading of the following "documentary" CPR text, I'll write in green for this section.

The following text, describing locomotive reconditioning comes from a 1946 CPR publication. It gives an interesting account of the processes used at that point.

Angus worked on steam locomotives for half a century so practices,

tools, and rolling stock evolved over time. As no one in 1904 planned

to slap together a webpage on early Angus processes a century later, most of

the good documents and stuff were probably all destroyed.

Canadian railways were often supervised by experienced British-born

railway managers, using equipment which was continually interchanged

(mainly freight cars) with American railroads. Heavy machine tools

manufactured in the US or Britain were common. Good steam locomotive

maintenance techniques (with some company idiosyncrasies) were often as "universal" as jet turbine

maintenance is today ...

...

well ... anyway ... this is how I rationalize the use of interesting

"foreign" photographs to illustrate some of the work at Angus.

I have used some illustrations from the UK and US to give you an idea of the type of work involved - particularly if there are workers shown in the photographs.

To

get things started, here is the "textbook" photograph of Angus at work

after World War Two ... the photo beloved and used by all.

But ... do you see any workers ?

One did get into the photo by accident.

(Play that "Shoot Waldo" game the kids love so much, and see if you can hunt him down!)

BEGIN CPR TEXT ...

The steam locomotive has a working life of from 30 to 40 years.

This span of life is determined by the boiler as all other parts are

renewable, and through periodical inspections and general

repairs locomotives are maintained in safe and serviceable condition for

the life of the boiler. The longevity of the active period of a

locomotive contrasts remarkably with the comparatively brief life of

some other forms of motive power.

Even in the early stages of the design of a locomotive, careful

attention is given to the arrangement, location and construction of

each detail, to the end that accessibility and facilities for renewal

of wearing parts may be provided.

It is the purpose of this article to outline the procedure by which the reconditioning of a locomotive is effected.

Selection of Locomotive for Shopping

The selection of a locomotive for shopping is determined by, several

considerations, of which the factors are the mileage accumulated since

previous general repairs, condition of boiler and firebox, date of next

internal inspection and tests, condition of machinery, and operating

requirements which may demand specific classes of power. Accumulated

mileage since the previous general repair may be varied in the case of

individual locomotives but in general a passenger locomotive would

average, between shoppings, 125,000 miles; a freight locomotive 80,000

miles; a switching locomotive 65,000 miles.

The locomotive foreman of the roundhouse at which an engine is

maintained, has a record of the mileage made by each locomotive, with a

general summary of its condition, particularly as regards boiler tubes

and firebox, machinery and tires. His recommendations, being

transmitted to the division and district master mechanics, are used as

a basis for the preparation of shopping lists, covering the engines

which it is proposed to shop. These lists, made up each month, cover a

period of three months in advance. They are then forwarded to the

Superintendent of Motive Power, who makes the final decision as to

which engines will be recommended for shopping.

Assuming the repairs will be made at Angus Shops for Eastern Lines

locomotives. A work report is submitted to cover the necessary visible

repairs required and authority is given by the Chief of Motive Power

and Rolling Stock for the movement of the locomotive to the shop. Upon

arrival at Angus examination of locomotive is made and an estimate is

submitted to the Chief of Motive Power and Rolling Stock, giving

particulars of the necessary repairs and the estimated cost to complete

same.

Preparation of Locomotives and Repair Operations

The first operation is to place the locomotive on a coaling pit. Any

coal remaining in the tender is removed, grates cleaned, ashes dumped,

fire brick arch removed from firebox and all water drained from the

boiler and tender.

From the coaling pit the engine is moved to the shotblast house, where

any pitted and scaled paint surfaces are thoroughly cleaned by means of

air-pressured shotblast. This cleaning includes wheels, cab and tender

when necessary, smokebox and jacket and any other parts which require

complete removal of old paint before the surface is suitable for

refinishing. For protection against rusting, surfaces which have been

shotblasted are given a priming coat of black paint, after which the

engine is taken to the erecting shop for stripping.

Upon arrival at the erecting shop, it is placed upon a stripping track

and stripping operations commenced. The tender is uncoupled from the

engine and taken to the tender shop.

The preparation of the locomotive for lifting from the wheels, requires

the removal of all guard stays, main and side rods and brake gear.

While this is in progress, smokebox front, grates, headlight,

handrails, dynamo, steam and safety valve casings and automatic fire

door are removed by the erecting shop gang. The jacket shop removes

firebox and cylinder jackets; the tank shop removes the netting and

plates from the front end and commences to strip the ash pan. The

carpenter shop removes firebox lagging, so that firebox may be properly

examined, when being tested, and cab seats, sashes and arm rests are

removed. The steamfitter shop strips the pipes for test. The engine is

lifted off the wheels by two cranes and is carried down the shop and

placed upon the pit where repairs are to be made.

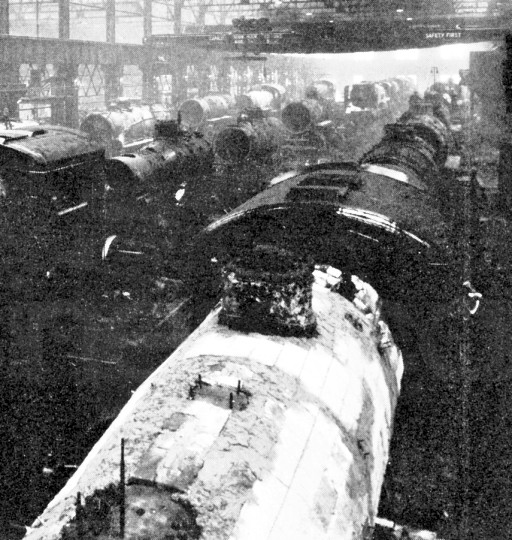

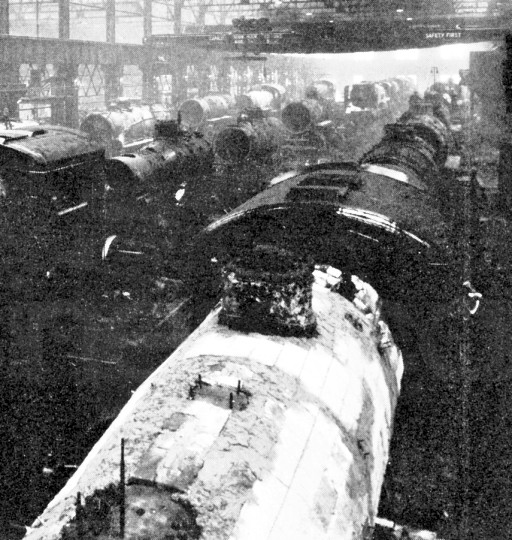

This hazy photo is a good impressionistic interpretation of Angus.

This hazy photo is a good impressionistic interpretation of Angus.

While neat and tidy shots from an overhead crane at Angus are often seen in books,

this photo brings the viewer a little closer to the worker's experience on the rebuilding "assembly line".

The machines being worked on are generally ... greasy and dirty,

harbouring little pools of mucky water, and all the components are extremely heavy.

On the closest locomotive, rough old boiler lagging is patched up with fresh white lagging pads.

Boiler lagging insulates the hot ugly riveted boiler shell ... from the outer cosmetic painted sheet metal.

Both the rough and fresh boiler lagging you see are are primarily made of asbestos ... the insulation of choice for steam locomotives.

At the far end, centre track, you can

see an engine with its smoke deflectors (elephant ears) still attached

before component stripping.

Two engines along down this line, you can see a couple of workers toiling atop one of the locomotive boilers.

When removed from the locomotive, all parts are sent to the various

shops responsible for them, each of which has a definite date for the

return of the parts, ready for application.

Assuming, for example, that it is desired to repair the locomotive on

an 18-day schedule, the progress of the principal work would be as

follows:

1st day : Stripping.

2nd day : Stripping, hydro test of boiler.

Not at Angus : An American locomotive undergoing a hydrotest.

This process finds boiler leaks using water under high pressure.

Steam - a high-temperature compressed gas holding great potential energy inside a boiler ...

is too hot and dangerous to use inside a shop.

The T-shaped device attached to the backhead (cab area) of the boiler fills the boiler with water.

Water spurting out like a World War Two submarine movie ... shows the boiler defect locations.

3rd day : Stripping completed and all parts cleaned and delivered; tube removal commenced.

4th day : Tube removal

completed; driving box brasses and wearing faces removed; valves and

valve motion cleaned and tested; main and side rods tested.

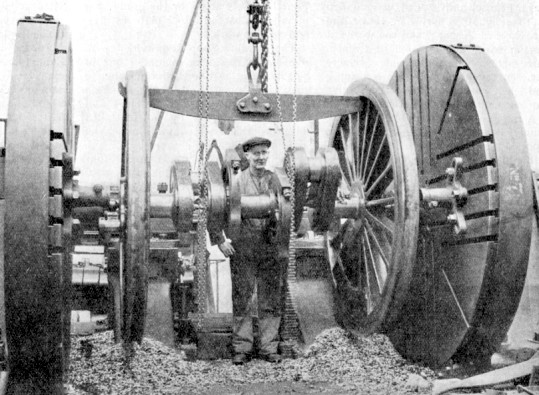

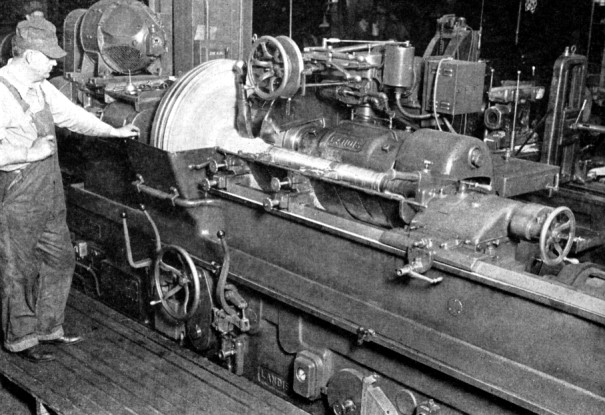

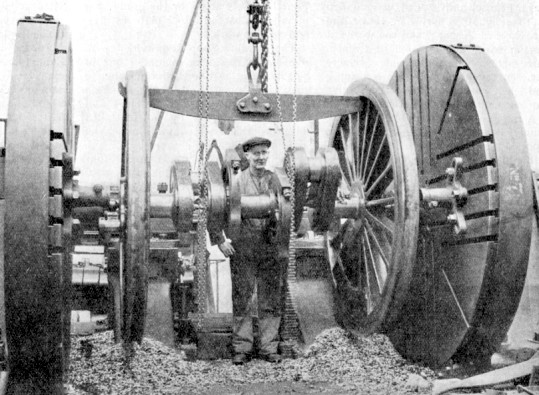

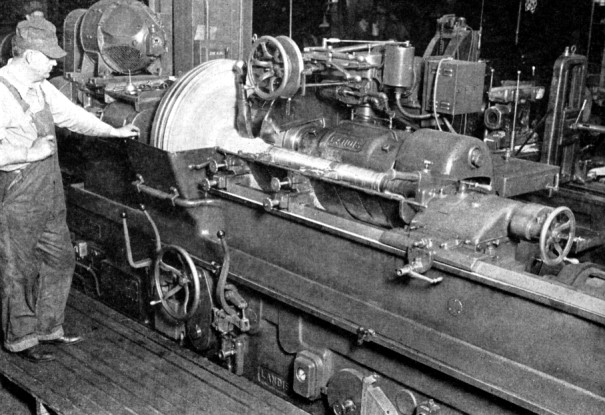

Not at Angus : At the London Midland and Scottish railway's Belfast [sic] shop

Not at Angus : At the London Midland and Scottish railway's Belfast [sic] shop

a driving wheel/axle assembly is "turned" in a special double-ended lathe.

The slotted outer wheels rotate the driving wheels/axle assembly.

You can see the metal shaved off the wheels on the shop floor.

Even to me, two things seem obvious :

During the process, the lifting device would not be attached.

The worker wouldn't stand there while the lathe was turning.

Special note : The British were generally into showier machinery often including steam locomotives with traditional inside (between the wheels) valve gear.

While most modern North American driving axles would go straight across, here you can see the inside cranks for the inside driving rods.

5th day : Old cylinder and

valve bushings removed; boiler scaled and smokebox cleaned; new driving

box brasses in; superheater header examined; frames repaired.

6th day : Cylinders repaired; driving boxes drilled; superheater pipes examined; motion work repairs commenced; dynamo cleaned.

Not at Angus: An American piston rod is being machined smooth.

Not at Angus: An American piston rod is being machined smooth.

By the worker's left hand you can see the grooves in the silver piston head for the piston rings.

7th day : Cylinders bored;

boiler patches applied; tank, tender frame, engine truck and cab

repairs commenced; dynamo repairs commenced; cab cleaned and primed.

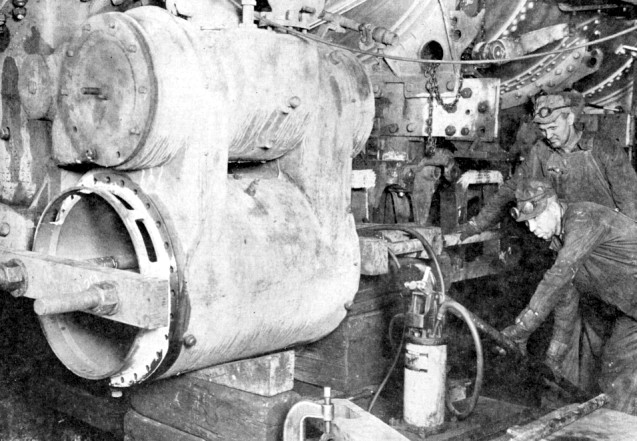

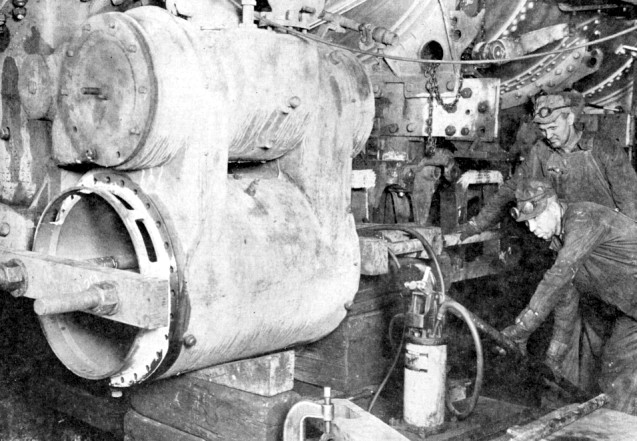

Not at Angus: The piston (previous photo) would be inserted in this tube, with the piston rod pointing out toward the workers.

Not at Angus: The piston (previous photo) would be inserted in this tube, with the piston rod pointing out toward the workers.

The piston

bushing - a hard-wearing liner inserted between the piston and the

cylinder casting - is being inserted with a "bushing puller" tool.

8th day : Frame repairs

completed; stay bolts applied and tubes welded; numerous frame castings

completed; superheater pipes finished; tender cleaned and primed.

9th day : Guard stays up and

shoes and wedges lined up; tubes cut to length and tested; pumps

repaired; superheater pipes fitted; cab doors and sashes completed;

first coat of black engine surfacer applied.

10th day : Boiler mountings

applied; tubes rolled and beaded; arch tubes, crossheads, guide bars,

dry pipe, etc.applied; spring gear delivered; inside of cab painted.

11th day : Dry pipe tested;

tubing completed and boiler tested; wheels and motion parts delivered;

headlight repaired; dynamo tested; paint rubbed down on tender and cab.

Not at Angus : The stripped boiler is separate from the stripped running gear in an American shop.

Not at Angus : The stripped boiler is separate from the stripped running gear in an American shop.

Instead of the British inside cranks, outside pins provide an eccentric connection for the rods.

Notice the cable slings behind the cylinders and at the cab.

While all the running gear was at other shops being worked on,

the

stripped boiler assembly could be deposited on a rollable shop frame,

or sturdy blocks of wood (previous photo), by the travelling

crane.

12th day : Engine wheeled and

trucked; dry pipe and superheater headers applied; valves, steam chest

covers and cylinder covers applied; tender brake details cleaned and

tested; boiler and cylinders lagged; coat of black engine finish

applied to cab and tender.

13th day : Main and eccentric

rods delivered; stand pipe applied; superheater pipes applied and

tested; jacketing commenced; lettering, numbering and striping on cab

and tender completed.

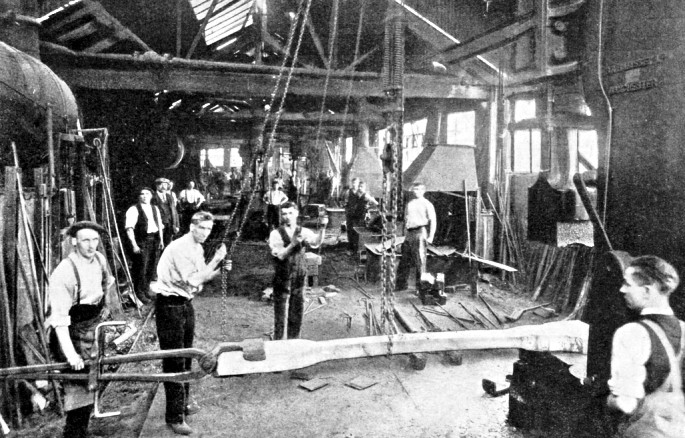

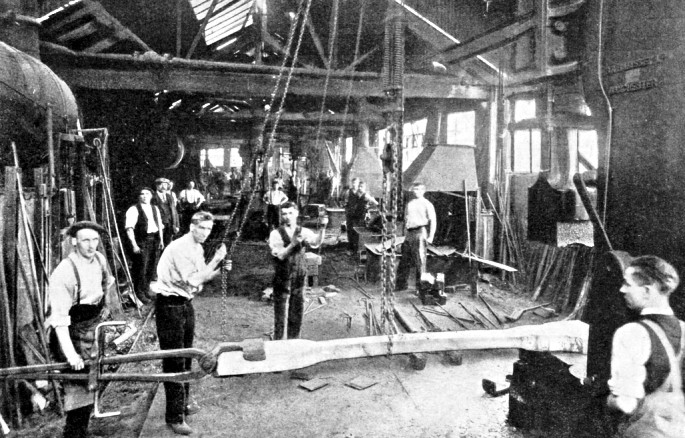

Not at Angus: Hammer and tong at WG Bagnall's at Stafford, England.

Not at Angus: Hammer and tong at WG Bagnall's at Stafford, England.

A steel billet for a connecting rod is manipulated with the tong and chains.

The hammer operator and the steam hammer itself are at the right.

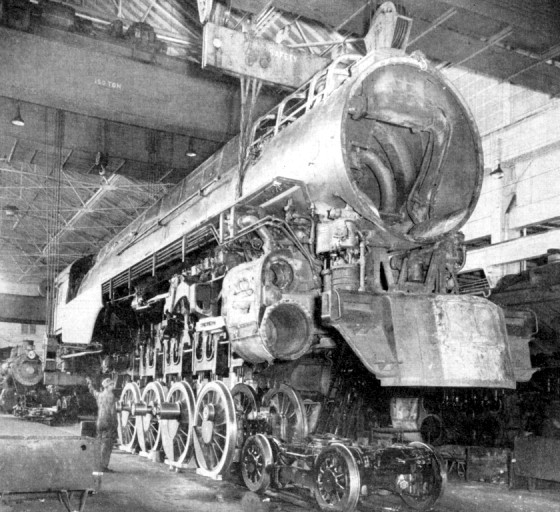

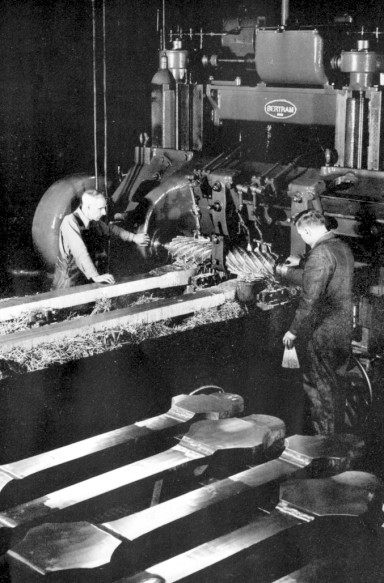

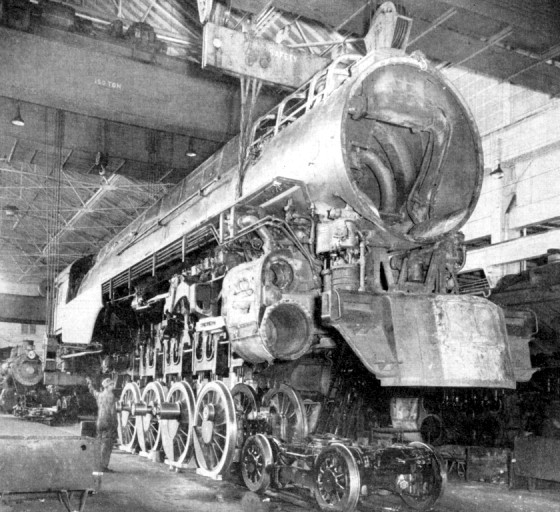

Angus in the 1940s.

Workers are currently milling main rods.

Nice, eh?

14th day : Valves set; steam and exhaust pipes applied; varnish cab and tender.

15th day : Engine blown through; pistons, etc. delivered; tender and tender truck repairs completed; brake gear delivered.

16th day : Grates, fire brick, arch, pistons, brake gear, ash pan and cab doors applied; tender mounted; 2nd coat of varnish on tank.

... END CPR TEXT

Phew! ... Fresh air! Time for a smoke.

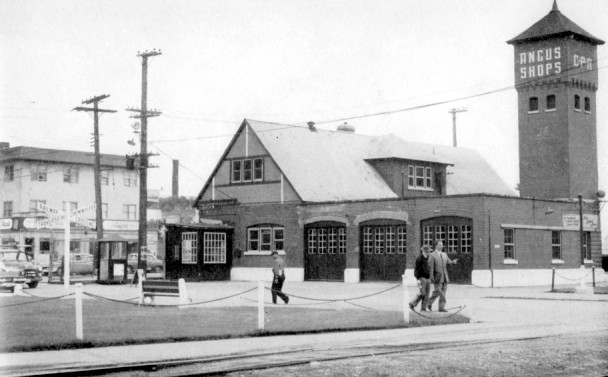

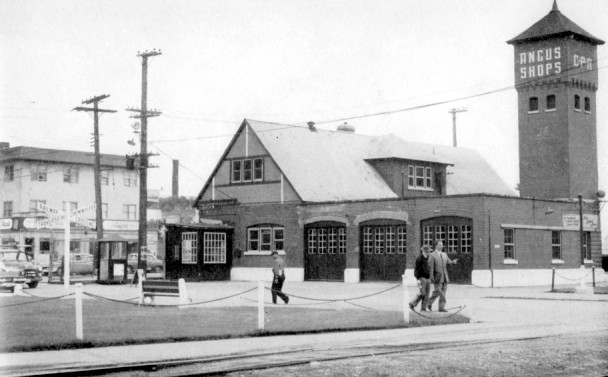

At the south Rachel (ex Nolan) Street Gate ... the police and fire station.

The two men are starting to walk north along the Midway.

The worker is walking out with a lunch pail under his left arm.

Legend, Forgotten History ... and Bureaucracy

Angus lives in history as the home of CPR's distinctive steam

locomotives. Consistent with a common railway practice at the time, the CPR's

motive power department did design its own steam locomotives.

However, after 1921 only 5 CPR locomotives were built from scratch at

Angus - out of a total of 1057 locomotives erected by the railway - first at

Delorimier, and later at Angus. In the modern era, contract builders Montreal

Locomotive Works and the Canadian Locomotive Company at Kingston, among

others, built the CPR's steamers.

As described in the 1946 procedures above, Angus had the capacity to

perform heavy locomotive "backshopping". However, contracting out the work

of new construction was probably cheaper and less disruptive to all the

other duties performed by Angus and CPR Motive Power. After the last

engines were constructed at Angus Shops in 1944, a particular class of 65 steam locomotives was completely

overhauled and rebuilt to a new wheel arrangement there between 1946 and 1949.

"The longevity of the active period of a

locomotive contrasts remarkably with the comparatively brief life of

some other forms of motive power."

... so stated the 1946 CPR article above. Maybe this official is not "buying in" to the new diesel technology ...

... hmm ... could be a problem ... "re-education" or "extreme prejudice" ? ...

As diesels invaded the railway, Angus Shops staff butchered great herds

of the silent steam mastodons with

acetylene torches on the outdoor tracks - from the mid-1950s until 1966.

A few decades later, Angus itself ended with diesel maintenance and a whimper - a shadow of its former self.

Today, the old heavy industry "remediated brownfield" has

disappeared under new residential development and is largely forgotten.

At the former site, Rue du Canadien-Pacifique, Rue de la Forge and Rue de la Fonderie - as well as some of the reincarnated buildings - today suggest the previous industrial use of this land.

And Avenue du Midway is the old midway of the facility.

Rue Omer-Lavallee

commemorates the late CPR corporate historian who preserved and

interpreted much of the CPR's steam power history ... his published 1960

salute to CPR steam was :

"In articulo mortis, Vale!"

Sometimes, the Canadian Pacific Railway had a passion,

but it also had quite a bureaucracy to protect the stock and the dividend ...

"You want that when ?!"

Bureaucracy is usually synonymous with inefficiency and intellectual ossification.

Today, we value "24/7 decisiveness" ... ACT NOW ! ... if you make a mistake ... SOLVE IT LATER !

Bureaucracy is seldom understood to embody the finest traditions of an organization - its enduring "institutional memory"

... which lives on after the latest "leader's" mission statement and

"messaging" has melted away like so much bumwipe flushed down on the

ties.

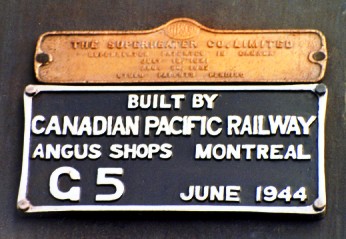

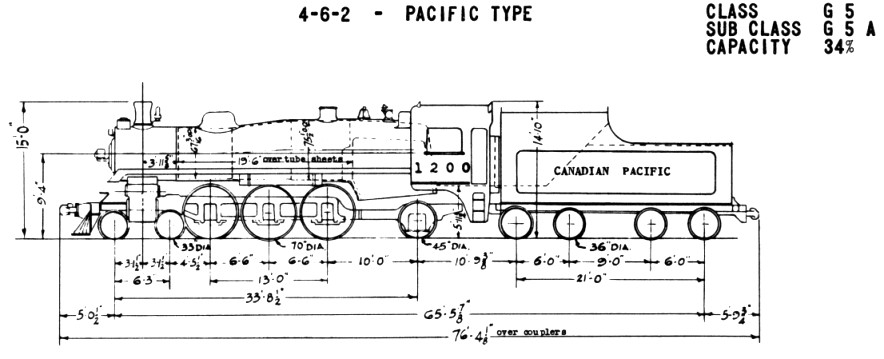

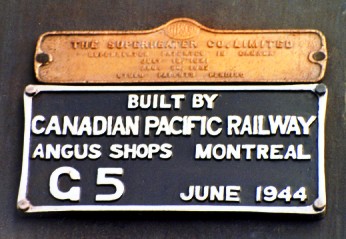

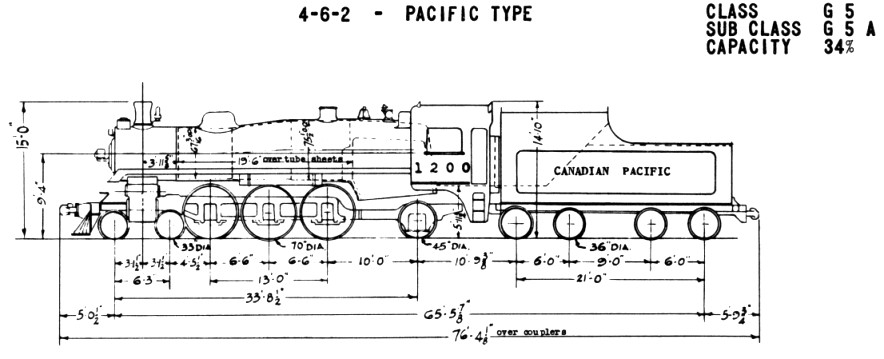

Below is one of two similar locomotives actually erected at Angus : road numbers 1200 and 1201.

"Pacific" is a standardized North American name for a steam locomotive

with a 4-6-2 wheel arrangement

... or Class "G" on the CPR ... or "the 1200s" to working road crews.

Anyway,

one hundred additional G5's of the same basic pattern followed ... but built by

Montreal Locomotive Works, and CLC at Kingston - not Angus.

The legend goes that CPR financial managers officially consigned 1201 to the acetyline torch in 1962,

but due to CPR "bureaucracy" the work had still not been done in 1966

when the locomotive was passed on to the federal government.

The story continues that the particular locomotive, 1201, had been

lost ... forgotten ... repeatedly shuffled to the back of the dead line ...

by shop staff because it was the very last locomotive built at Angus.

When it operated out of Canada's technology museum,

we rode behind restored locomotive 1201 ...

Ottawa to Wakefield, Quebec and back - in July 1982.

Below, 1201's turbogenerator sings as it simmers on the main track at Wakefield - just before our return to Ottawa.

Of course, it's builder's plate was on proud display and demanded to be photographed that day ...

Of course, it's builder's plate was on proud display and demanded to be photographed that day ...

151 years after the birth of Richard Bladworth Angus in Scotland.

Known for his clear-eyed financial analysis ...

it would be interesting

to know the thoughts of RB Angus on the CPR's bureaucracy in 1962 ...

and its failure to scrap this locomotive in a timely manner.