Railways on the Farm - The Dairy Barn Monorail

- Books on the history of rail...ways generally mention coal mines within

the first couple of chapters.

- If a person, pony, or horse was going to move a cart of coal out of

a horizontal mine shaft, running on a smooth surface, such as wood or metal

rails would make things easier.

- Pre-railway steam engines, using condensing (contracting) steam were

used to pump water out of coal mines.

- Then the inventors of the industrial

revolution decided to try confining and compressing the steam well above normal atmospheric

pressure ... and using it expansively as it "rushed downhill" to STP.

- Coming together like chocolate and peanut butter... compressed steam

engines for traction, and rail ways, bumped into each other.

- Many books and websites were subsequently produced to celebrate this.

While rail equipment propelled by steam, electricity, and sometimes horses gets all

the attention,

this page will discuss an extremely successful Canadian monorail which used none of these.

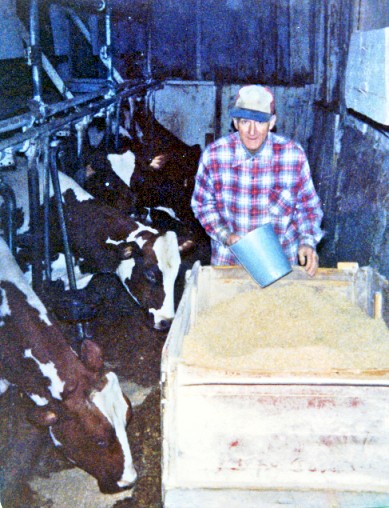

This page is about the best job and the happiest times I ever had.

"Uncle Douglas !"

Camera ready, I'm suddenly shouting at my great-uncle over the noise of :

- the exhaust fan above our heads (to control the body heat and humidity coming from the cows)

- the radio ... usually AM 800 CJAD Montreal ... sometimes CKMF et le Disco Weekend avec Guidi DuBois ! ... for transient Ontario farm hands.

- the loud buzzing rattle of the milking machine vacuum pump

- the cows (purebred Ayrshires) ... drinking and slurping, coughing, sneezing, mooing, crashing against their stanchions, and jingling the stanchion chains

Unfortunately, I didn't really set my great-uncle up for a

1978 Sears Portrait here. I can still feel that worn old 3-wheeled cart, containing

around

300 pounds of grain, as I helped him feed by shoving and dragging it around.

The single swivelling wheel (currently on his end) facilitated

tight 90 degree turns. Working at the opposite end to the "locomotive", my uncle metered

the grain based on the cow's state of gestation, lactation, or going dry-ness, etc. The grain cart's steel wheels,

clattered down and up the grooved concrete ramps of the route between

the manger (food trough); the gutters (ex-food troughs), and the manger

on the other side.

This grain blend (including molasses flavouring ; non-protein nitrogen ... urea ; mineral &

vitamin supplements) was

fed in the barn at both milkings. It completed the cows' diet of

grass (or corn silage, in season) and dry hay. In particular, it provided the

extra energy necessary to produce calves and milk. In summer it was purposely

fed inside the barn to draw the cows off the lush and tasty timothy and

clover of

the new summer pasture ... for a two hour milking session

As a 16-18 year old farm hand, it was my job to

refill the grain cart by dumping 100 pound burlap bags of the grain

blend into the old cart. During my three 70-day summers ... I would

have hefted and emptied

about 52 tons of grain into this cart. It would be interesting to

calculate the ton-miles run up by this vehicle during its half-century

of

captive service along the concrete-ways of the barn.

In a dairy barn with stanchions, the "business end" of the cows is their

tailends. During a two hour milking, you would only visit the headends

a couple of times.

A Bluffer's Guide to visiting a dairy barn with stanchions :

-

GO

BEHIND ... contemplate the cows' udders ; girth (although

many are pregnant too) ; pin bone spacing ; legs and feet ; and showy straight toplines

for 5 -10 seconds per cow.

- Don't wear light coloured

clothes or good shoes ... Uncle Douglas often regaled us with a

cautionary tale with a tragic ending : "He came in here dressed in white like

the Prince of Wales !"

- Step calmly and slowly away from tails which

show signs of rising - 3 or 4 feet should do it ... unless the cows are just

out on new grass and/or sneeze at the same time, etc, etc.

Successful bluffers avoid : Patting cows on the head. Commenting on nature's smells ... instead meditate on : "grass and water ... grass

and water ..."

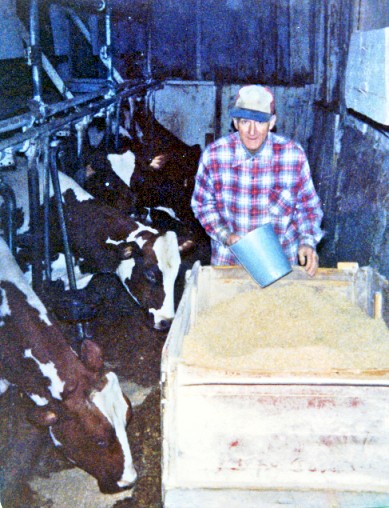

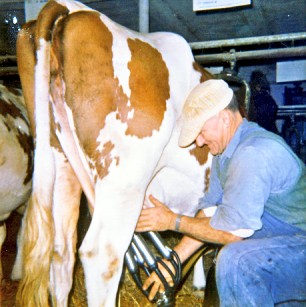

January 1974

Douglas is finishing off a cow's milking.

Douglas is finishing off a cow's milking.

While completely automated milking

parlours are common in the 21st century, my uncle stated that "there's nothing

like the human hand".

And when he started in the business, the milking machines WERE hands.

It looks here as if he is finishing off the two back quarters, the front two having milked out more quickly.

It has been my experience that Douglas or Bob could photo-identify a

cow from "this view" 10-20 years after it left the barn for the last

time.

On this farm, it was essential that the milker knew each cow's particular milking characteristics,

and that the machine was taken off as soon as possible to avoid irritation.

Perhaps the most significant single development in dairy farming technology was rural electrification.

Above all, it made electrically powered pneumatic milking machines possible.

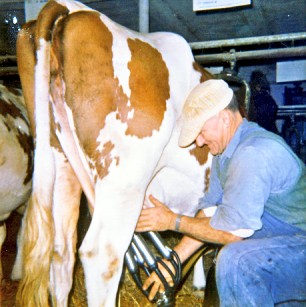

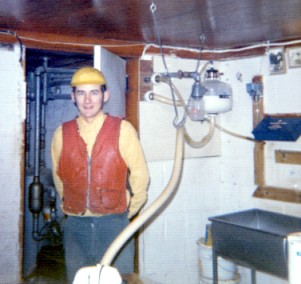

My cousin Bob is emptying the milk from a single cow's milking into a dump station.

Using the same pneumatic system as the milking machines,

plastic and glass tubing takes the milk to the milk house where it is cooled in the bulk cooler tank.

The summer before I began working in 1973, it was still the "summer student's" job

to physically transport and dump the milk into the cooler in the milk house.

Over Bob's left shoulder is inverted railway rail from the ill-fated St. Andrew's Junction Railway Company.

Part of a working railway along the back of the farm for two years, it has held up tons of hay for over a century.

(Notice the other track near the fluorescent light ... for later)

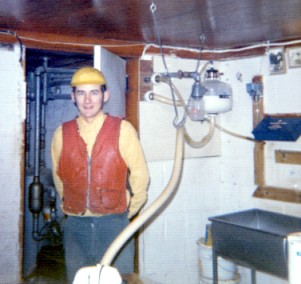

Inside the milk house

The pneumatic pump for the milking equipment is outside the door at the left.

In the milk house, the milk collects in the glass reservoir before being pumped into the bulk cooler.

All the tubing and equipment was disinfected daily and the purchasing dairy performed bacterial counts on every pickup.

This farm's milk was generally the cleanest of the 30+ farms on the route.

The dairy's tank truck came after four milkings : evening/morning-evening/morning.

During ice cream season, they sometimes came more often.

This is what has been collected in the empty tank after one milking - the darkness is lit up by my flash.

The curved walls and floor of the stainless steel tank contain refrigeration coils.

Milk can be seen flowing into the far corner from the glass reservoir.

A slow motorized paddle ensures rapid, uniform cooling.

Ayrshire milk averages over 4% butterfat and this quickly sticks to the cold squeaky-clean tank.

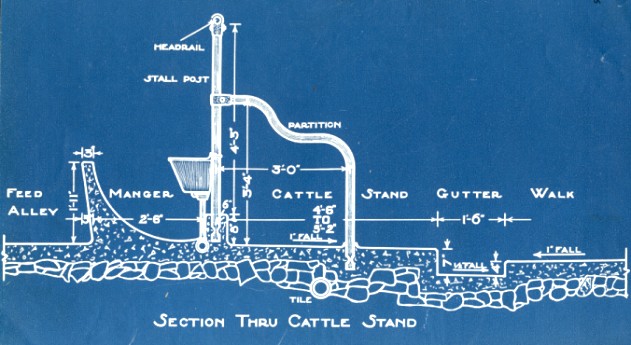

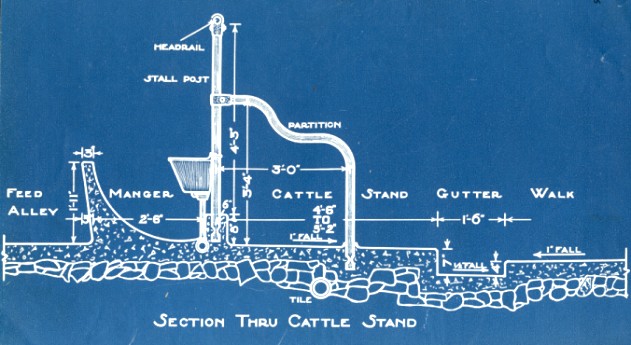

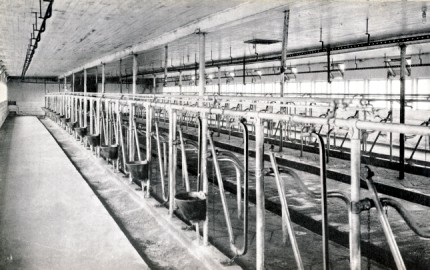

Cattle Stalls in the early 1900s

From standard plans from around 1920 you can see a cross section of a basic dairy cow stall.

From standard plans from around 1920 you can see a cross section of a basic dairy cow stall.

The water bowls were gravity fed from a single barn reservoir.

When it was too cold to continue pasturing, cows would spend their time in their stanchions with periodic exercise sessions.

There was never heat in the barn to keep the pipes from freezing ...

even in winter, the cows' body heat always maintained the temperature between 50 and 60 degrees F.

The "stall post" above is the balancing point for the Dairy Farm Hand's Winter Equation :

hay + silage + grain + water (20 gal) = milk + heat & water vapour + animal bodily waste

The floors of the stalls were concrete, so significant amounts of

fresh straw and/or wood shavings were placed under the cows daily for

bedding.

This material adds to the tonnage of the right side of our equation.

The "one inch fall" notations above are essential to ensure

that liquid waste drains into the gutter.

The bedding and animal waste form a unique composite material (manure) which you can remove with a fork ...

but you'll want to use old bedding and a shovel to get every drop !

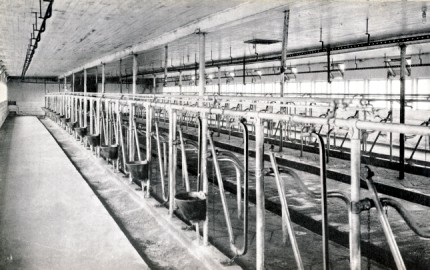

The Canadian barn above is equipped with the same brand of furnishings my uncle and cousin had.

The farmers work in the centre aisle where the action is.

The two ranks of cows get to look out the windows as they dine.

Above the windows, you can see open "clerestory" ventilating doors to control heat and humidity.

(Notice the tracks above ... for later)

My father took this picture at the farm in April 1961.

My father took this picture at the farm in April 1961.

Back then, all the cows were equipped with horns - including the "evil cow" with the flash eyes.

Notice how the smooth concrete floors disappear under "toasty late winter hay treats",

making the use of wheeled vehicles difficult.

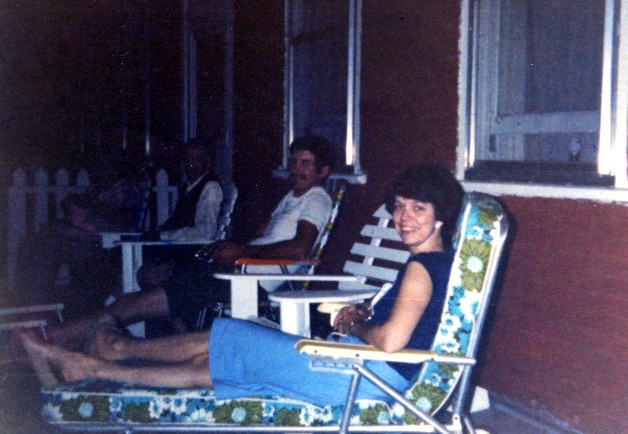

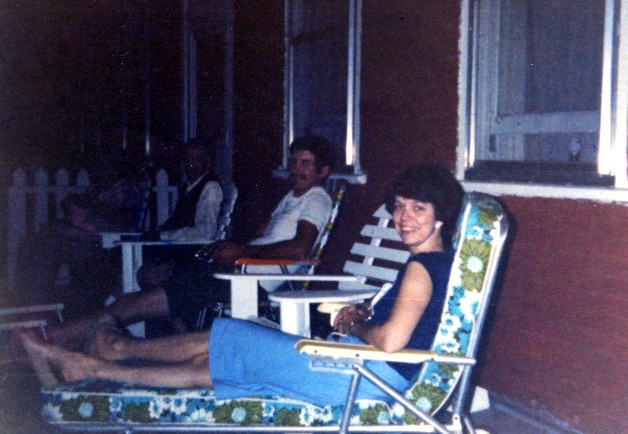

Taking a break outside

I enjoyed my farm experiences very much.

While working at the hospital (and single) I often spent weekends - and

sometimes vacations - visiting and "working" on the farm for several

years.

These additional experiences were possible due to the patience and hospitality of these people.

Down in the night pasture by the "tank bridge" Bob and sons Michael and Andrew pose near the end of an autumn afternoon.

Down in the night pasture by the "tank bridge" Bob and sons Michael and Andrew pose near the end of an autumn afternoon.

Bob's wife May in the foreground.

Bob's wife May in the foreground.

May provided all the hotel services I enjoyed during my many, many ... many visits.

In June 1978, we have just attended the Lachute Spring Fair visited by future Prime Minister Joe Clark.

We sit on the front gallery in the dark because ... "you can't do this in January".

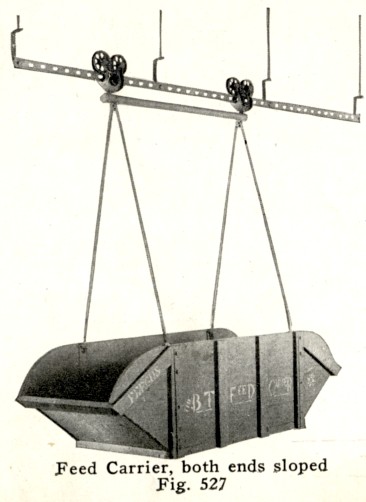

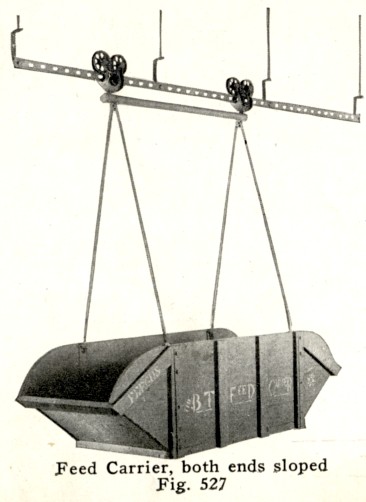

The Successful Canadian Monorail

The Beatty Brothers farm equipment company manufactured the hardware used in the barn,

including the very successful Canadian monorail.

At the top of this page, we were moving 300 pounds of grain around in a cart (steel wheels on concrete)

and that the manger aisle was often covered with hay which the cows were happily playing with.

Here was one possible grain solution ...

Using a simple monorail track which could be attached to the joists above,

Using a simple monorail track which could be attached to the joists above,

steel wheels on steel rails could have carried the grain above the obstructed floors.

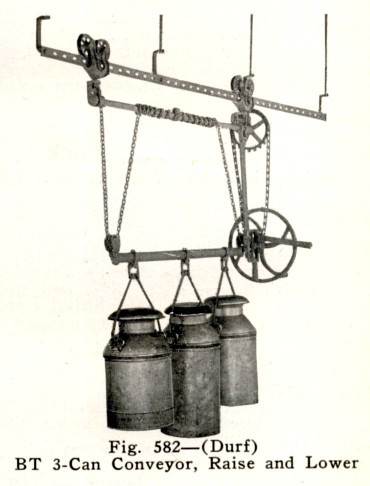

Moving Milk before pipelines

Before electricity, milking machines and refrigeration ...

pails used for hand-milking were emptied into large milk cans.

Originally, the cans were taken for cooling by ice or cold water ...

before being loaded onto horse-drawn wagons or sleighs ...

to meet the "milk train" which eventually delivered to the dairy.

For this farm in the "old days" it was the J. J. Joubert Dairy in Montreal.

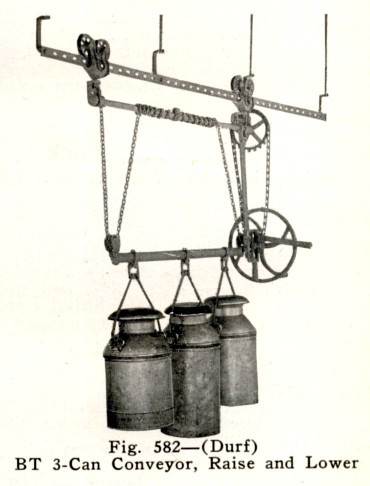

Using the same type of track throughout,

cans could have been moved from barn, to cooler, to wagon,

with minimal manual carrying or lifting.

(Durf is the product name code)

The Rail System

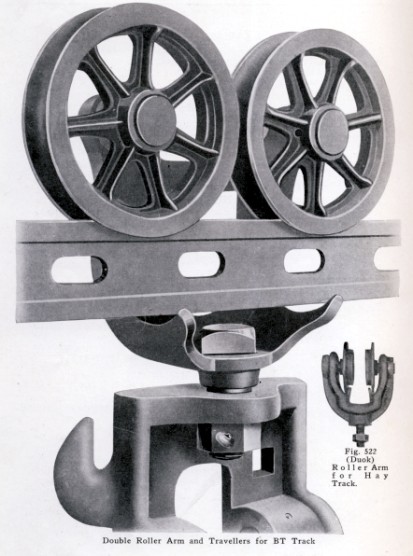

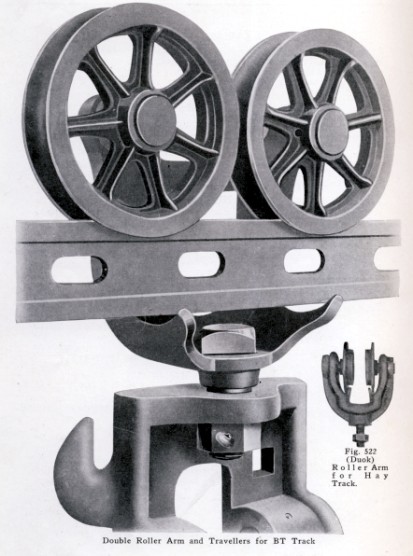

Here is an illustration of the wheel assembly which resisted derailing.

(Connoisseurs will look at this illustration and correctly predict a seasonal summer webpage to come in the future)

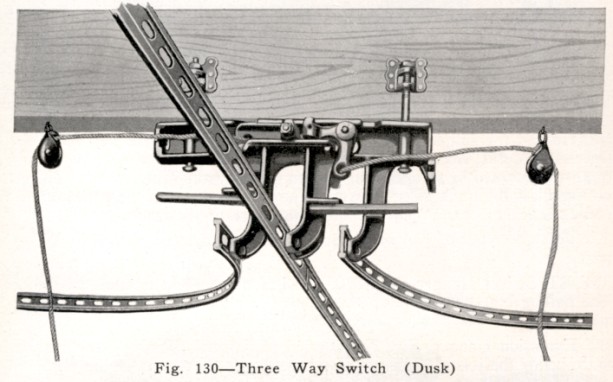

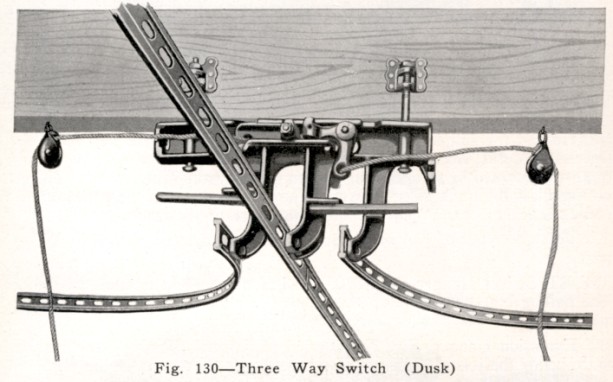

Here is one of the switch assemblies used to route the various types of cars.

Here is one of the switch assemblies used to route the various types of cars.

This "three rail stub switch" was lined and locked for the route to be used ...

by pulling on those two cords in the correct sequence.

(If you stare at it, you too can become a barn switchtender)

Notice the simple system for mounting the track on wood.

During installation, the track could be bent to perfect curves around farm wagon wheels.

I am not the first person to notice the "railwayness" of this equipment.

My uncle told of previous farm hands who supplied sound effects for

steam whistles, locomotive exhaust, and air brakes when operating this equipment.

The Monorail I Knew

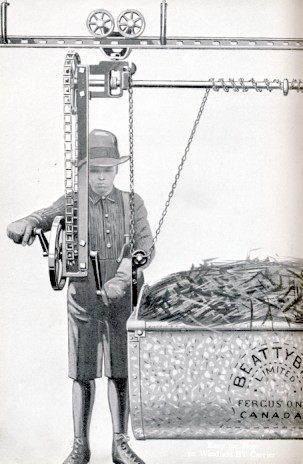

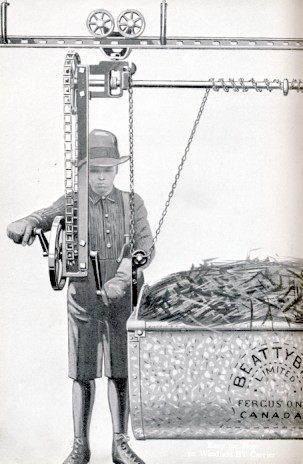

My practice was to dress up in my best hat, shorts, and leggings to load up the farm's litter (manure) carrier.

My practice was to dress up in my best hat, shorts, and leggings to load up the farm's litter (manure) carrier.

Before electric stable cleaners, it was either this or wheelbarrows to carry out the manure.

Manure is frequently close to water in its density,

so you can imagine the weight this happy little tyke is windlassing to the appropriate altitude,

for transportation over obstructions.

Still in service after all those years - the Beatty manure carrier.

Below, in 1978, Bob with long-time farm friend Michael, is cleaning up the "horse stable"

which is housing some of the newborn calves and other young, non-milking stock for the winter.

First, can you understand why this was refreshing weekend work for me?

... when compared to hospital politics?

Write a two page essay discussing the contrasts and similarities.

Second, if you were Michael, wouldn't you be amused that someone was photographing this operation?

Below, bringing a load from an isolated corner of the dairy barn which was not yet served by an electric stable cleaner,

Bob spots and dumps the load directly into the tractor-hauled manure spreader.

White "quick lime" - formula CaO - is sprinkled on freshly cleaned soiled surfaces to sanitize them and make them "farm fresh".

Here, in 1978, is a showroom fresh manure spreader.

Using the "power take-off" shaft of the tractor ...

chain drives, pulling full-width steel bars along the spreader's bed ...

slowly move the load of manure toward the back.

At the back, the rotating shaft of serrated paddles throws the manure all over the place.

"Don't fork yourself ...

Clean the gutters by pressing a button !"

... so an early advertisement for electric stable cleaners could have read.

This shot is looking in the opposite direction to the "dumping" photo,

and you can see the same monorail track section (left, above) from which Bob was emptying the load.

To the right, you can see the circa 1960s electric stable cleaner ...

on the occasion that the Pattie Stacker tower was being dismantled.

The red object at the top is the electric motor...

which slowly drags the groaning continuous chain of paddles ...

in a circular path through the stable's gutters.

The paddles travel loaded up the right side ... dump ... and come down empty at the left.

The installation was being shortened to dump directly into the manure spreader.

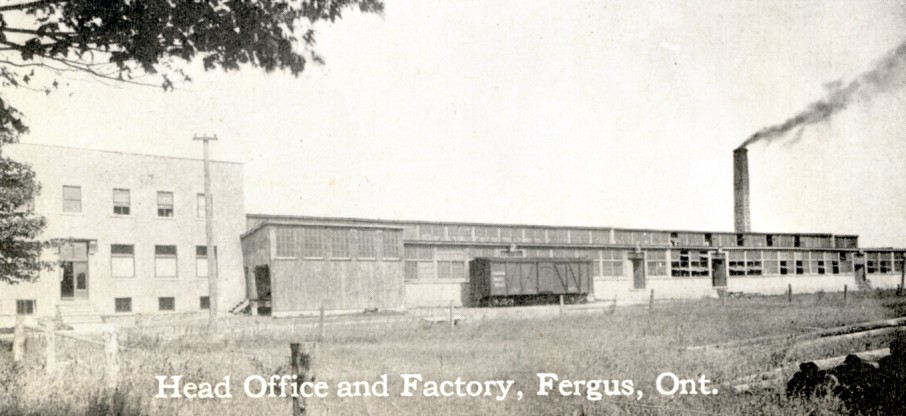

From the home office in Fergus in the 1930s ...

Above is one of Beatty's farm equipment factories.

Above is one of Beatty's farm equipment factories.

Coal is burning for shop power.

The summer weather is encouraging people to use natural air conditioning.

To finish up ... "original equipment" ... February 1962

(photos: LC Gagnon)

The Volkswagen is the frosty family car which brought us up from Lachine on this very cold morning.

The Volkswagen is the frosty family car which brought us up from Lachine on this very cold morning.

Behind the silo (containing September's fermented chopped corn plants - corn silage) is the dairy barn.

The green gabled "tractor garage" was once the spot where the large milk cans were stored.

The horse stable (notice the horses) and a granary are at the left.

As my uncle told me, there was once a "post office" behind the closest red door (hint: before indoor plumbing).

Behind the horses in the yard, you can see steam rising.

With the big door open, someone is cleaning out the horse stable this morning.

The horse on the right is named Birdie - a rare non-Clydesdale on this farm.

The horse on the right is named Birdie - a rare non-Clydesdale on this farm.

The driver, who worked on the farm for over a decade is Telesphore LeBlanc.

The hand-loaded - and hand-unloaded - manure sleigh from the photo above, is returning empty from a trip to the field.

Shortly after this photograph was taken ...

tractors, powered manure spreaders, and an electric stable cleaner took over.

Back to sitemap