How the Newfoundland Railway fought mountains of snow

A quick study of the steam rotary snowplow.

From the original 1892 Newfoundland government decision until the

very end of the railway the Newfoundland Railway had a problem.

... Well more than one, but this particular one was formalized into

the Reid construction contract of 1893.

Recall that originally, the railway was going up to the north shore,

to Hall's Bay, a port which was clogged with ice for about half the year.

Suddenly, the new inspiration was to swoop around to the southwest corner

of the island to Port aux Basques - which created an elegant connection

with a new ferry to North Sydney, Nova Scotia on the Canadian mainland.

The problem came from a classic railway construction conundrum. Pay

now or pay later.

A) If a railway built a top quality route that was cheap to operate

- it might go bankrupt before it ever opened.

B) If a railway built a quick'n'dirty route, it would cost more to

operate forever - operating costs might bankrupt it after a few bad years.

Reid was told to follow the most direct route to Port aux Basques

- it had already been surveyed by government engineers. The Newfoundland

government was getting a cheaper railway by following this direct route,

and Reid, as a railway builder, was suddenly getting paid to build all this

extra track to Port aux Basques.

So no one asked too many questions and everyone was happy ... at least

in 1893.

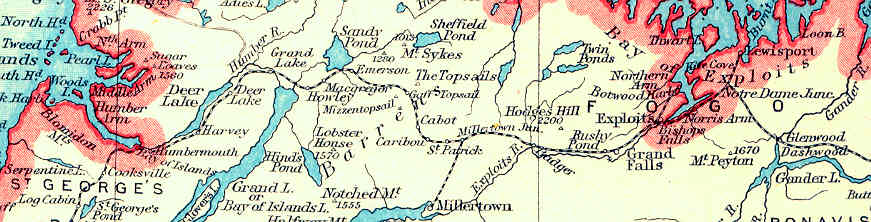

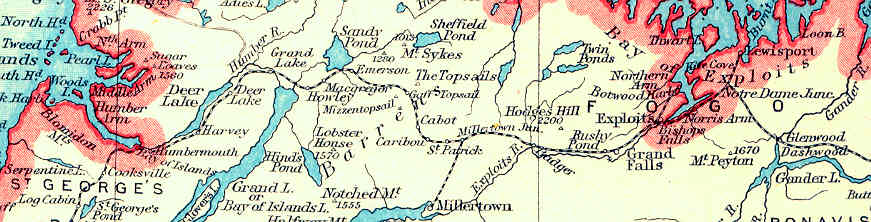

Here is a map which includes the location of the problem.

We have Humbermouth (the future Corner Brook) in the west and Grand Falls and Bishops Falls

in the east. The railway is the black and white line. In this circa 1923

map, do you see in the centre where it says "The Topsails"? Throughout

the railway's history, "Gaff Topsail" (also shown) was "the problem". To

appreciate the value of the neighbouring real estate, note that this area

is labelled "Barrens" ... as in "The Great Barrens".

An eminent railroader A.R. Penney wrote : "The direct route over the

Gaff Topsail was feasible but it was certainly not practicable. The railway

should never have been built there".

Some accounts say this "direct route" saved 60 miles of additional

track. In the western Canadian mountains, a big transcontinental road like

the CPR would have made do initially - then spent extra money to tunnel,

blast, and/or reroute its way out of trouble a few decades later as traffic

built up to pay for, and demand, the change ...

However, this was a light traffic, narrow gauge railway designed to open

up the interior at a modest cost.

The problem was snow.

Newfoundland can get lots of snow anyway.

At an elevation of about 1700 feet, the Topsails area was a snow magnet.

To see a real gaff topsail :

- Take out a Canadian dime.

- Look on the "Bluenose-like schooner" on the reverse.

- Squint - if you're my age.

- Locate the "D" in Canada.

- The wee little sail closest to the D is a (main) gaff topsail.

- Trailing the first tall mast is another (fore) gaff topsail.

The "gaff" is the spar - the pole - which stretches out this little

topsail at its bottom.

As rigging designs evolved over history, these tiny topsails became redundant, atrophied,

and dropped off into the ocean.

... But doesn't that tell you something about the proud seafarin' culture

of Newfoundland ?

Get as far as you can, horizontally and vertically, from the ocean

and still name things after ship anatomy !

Geologically, the topsails are called "tolts" (official Newfoundlandese),

inselbergs, or monadnocks. They are steep, solitary rock knobs that rise

100 metres or more above a surface which has been ground flat by ice sheets.

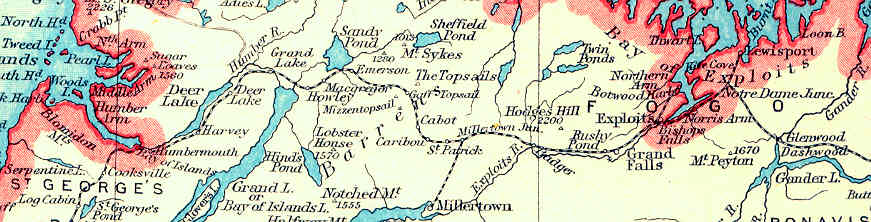

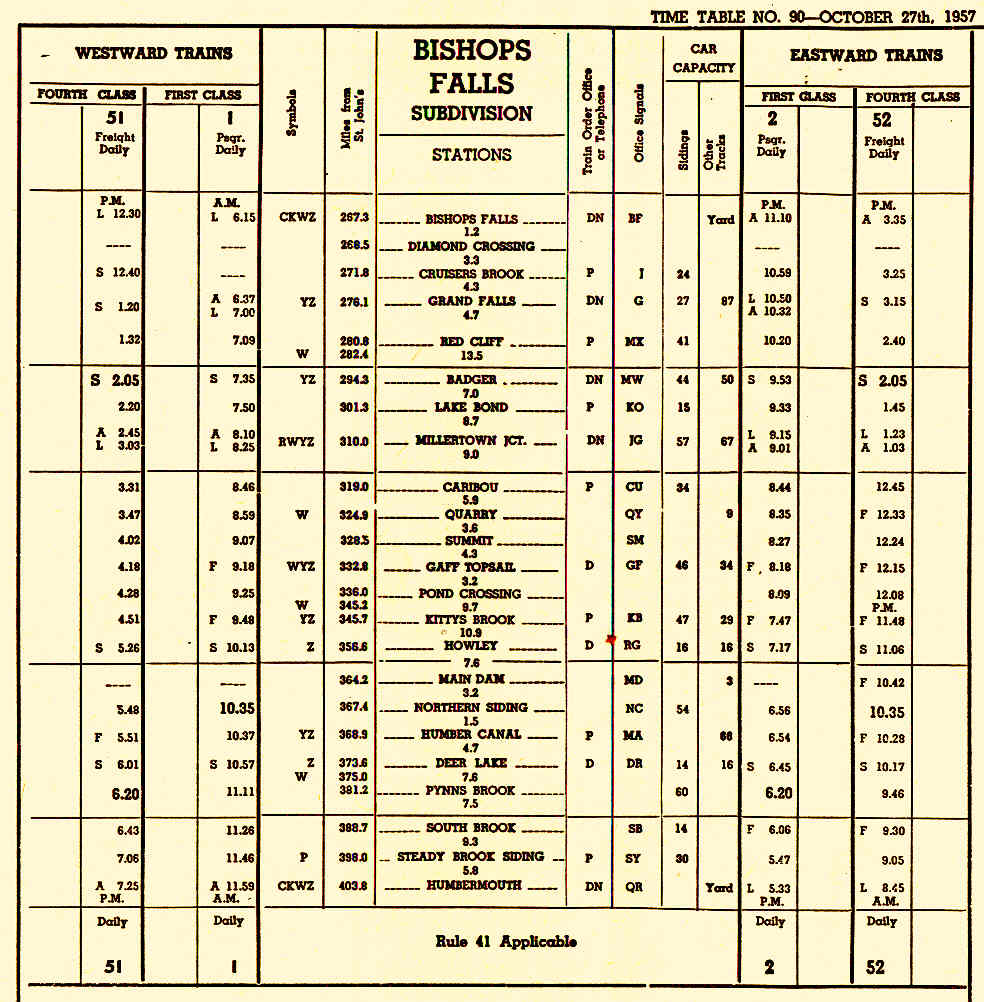

Here is the CNR employee timetable from 1957 for the stretch of line

between Bishops Falls (east) and Corner Brook (Humbermouth Yard) which is

to the west.

Gaff Topsail is only a flag stop (F beside the train times) - the trains

would only stop if someone beside the track there was waving or signalling to stop. However,

the location has water (W) for steam locomotives, a turning track (Y) and

its 80 car capacity "yard" is protected by yard limit signals (Z). As well,

it has a daytime (telegraph) operator (D) to provide operating orders to

trains. All this for a little spot in the middle of nowhere. Why do you think that was?

When this timetable was being issued, Sputnik had just been put in

orbit by the Soviets, and the Newfoundland Railway had replaced most of its steam locomotives

with diesels.

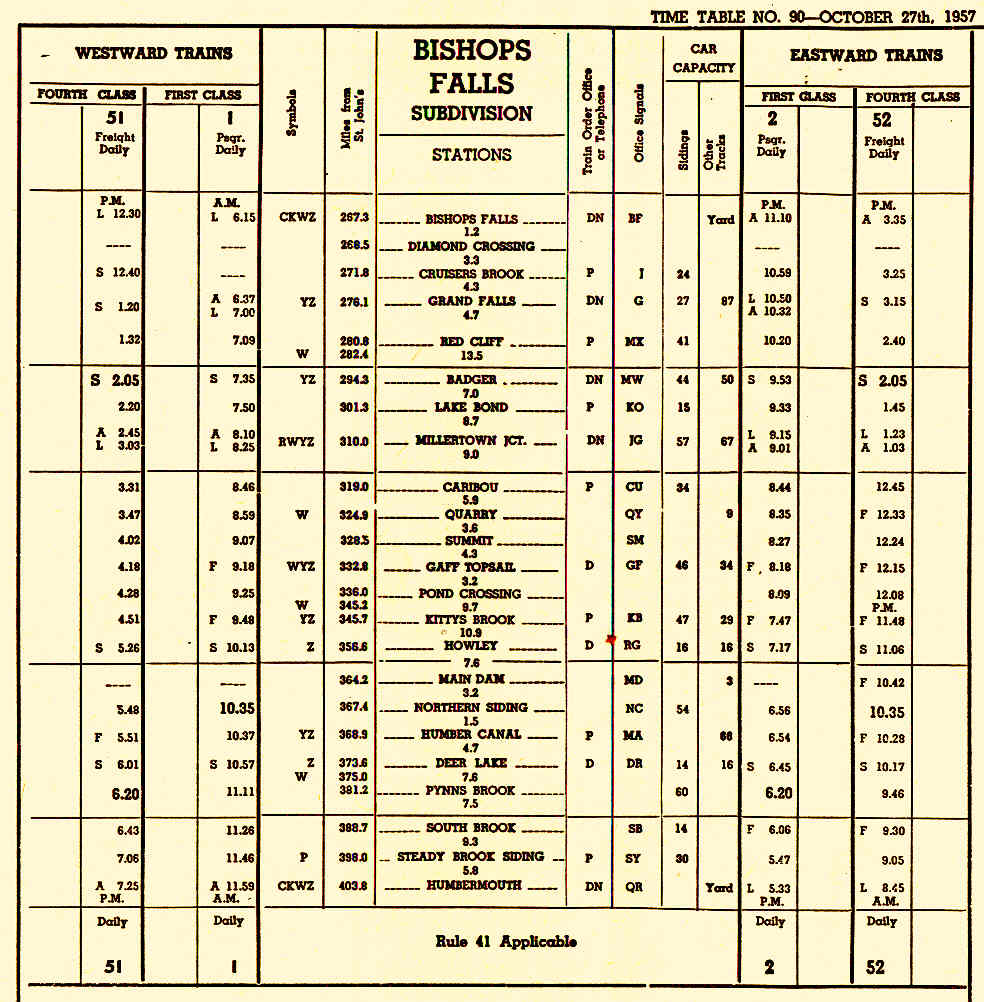

In 1988, here is Bishops Falls station. For many years, the western

half (everything behind the camera) of the Newfoundland Railway was dispatched

from this office. It was also the site of essential telegraph "repeating

equipment" - used to boost signals as they travelled across the island.

It was the west end Bishops Falls dispatchers who pulled out large clumps

of hair as they tried to keep trains rolling over Gaff Topsail.

However, let's go back a little further to the early 1900s to see where

the tradition of dispatchers pulling out their hair began.

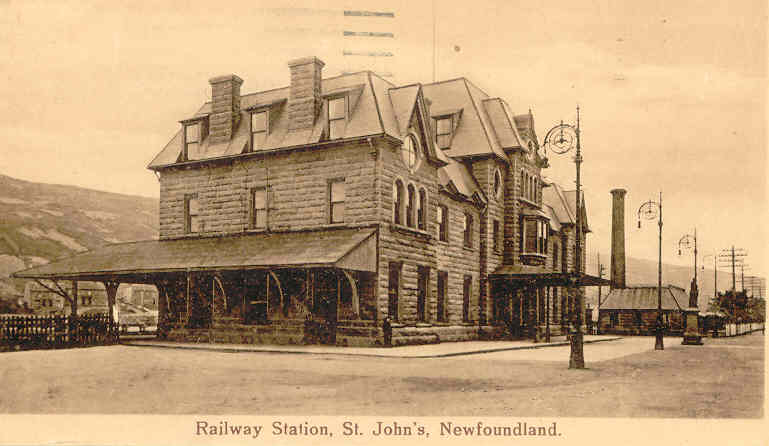

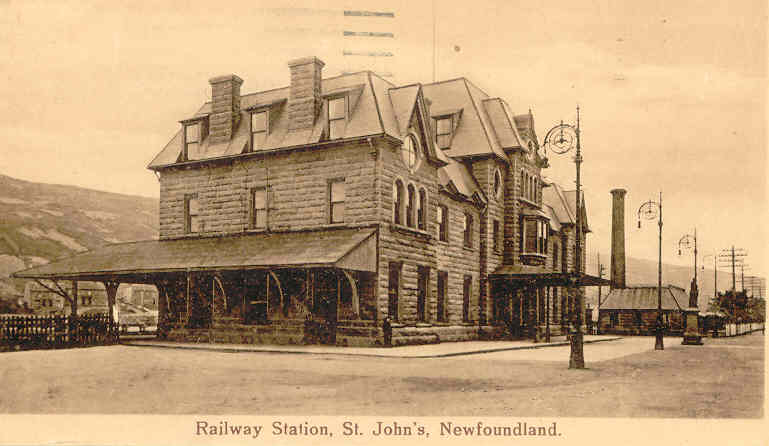

Behind the photographer is St. John's harbour and the entire Newfoundland

Railway lies before us in the west. Just beyond the station is the yard's

steam plant for heating buildings and probably for warming up locomotives

and passenger cars which are being readied for service.

Upstairs, you can imagine the dispatchers looking at employee timetables

and the large paper train sheet on which they chronicled the progress of

trains across their territories. They were told of the trains' progress by

telegraph operators on duty at stations along the route.

A large book recorded the precisely-worded train orders sent out by

telegraph by the dispatchers. As affected telegraph operators signalled

the words back, the dispatcher would underline each word or figure in the

book before finally signalling the order was OK to use ... or "complete".

He would then provide his three initials as authority to deliver the correctly

repeated instruction to the crews of the trains affected and those initials were then recorded on the order.

Inside each dispatcher's head whirled railway rules, knowledge of the

work habits of the crews and telegraph operators, mental calculations about

speed and distance and time for regular and extra trains (and worries about getting traffic over Gaff

Topsail in winter).

If it was quiet on a night shift with only a couple of expresses running

on 547 miles of track, the solitary night dispatcher might just have a nap

and all that poetic "whirling head business" would stop for a while ...

until the telegraph sounder clattered.

On days and evenings, the Chief Dispatcher was the all purpose "go-fer"

who had to make sure nothing fell through the cracks. The dispatchers went

to him with problems requiring deep thought and experience ... or at least

decisions over which they were not willing to risk their careers.

Also in the offices here were the Reid brothers. Whenever something

big was happening, at least one of them could be counted on to be present

as he supervised the railway which his Reid Newfoundland Company was operating

through those dispatchers.

The snow at Gaff Topsail was so bad that the line would sometimes be

closed for three weeks at a time until it could be cleared. Some photographs

show the snow up to the tops of the cars. In the early 1920s when the Reids

wanted to get out of the railway business, the east and west lines were

operated separately as an economy measure. Nature was left to do whatever

it wanted around Gaff Topsail and no one bothered with the railway line

through there until things started to melt. It was a lot easier on the dispatchers

when everyone just gave up on getting trains through that area.

There's no business like snow business ...

Elsewhere on this website, you can see old locomotives with their own little

snowplows built on to the cowcatcher. If the snow was just falling and

starting to build up, these little plows would help get the train through

to a major station. However, if the snow was falling or drifting heavily and it had

been some time since the last train went through, more robust equipment

was required.

Enter the snowplow.

At Corner Brook, in ... 1988 ... is a veteran snowplow from the 1950s.

Although the Reids' plows probably had significant wood content, this one

has lots of steel. The other cars are shown for the benefit of any modelers

out there ... they love quaint old sagging wood frame cars because they

are a challenge to model.

This unpowered plow would have been coupled to the front of a locomotive

and pushed through the snow. The snow would rush up the front ramp and

be thrown off to the right side of the track. Important note for later:

If the snow "walls" on the right side were higher than perhaps that

side window, the snow had nowhere to go - the plow movement would come to

an uncomfortable stop. (That orange thing sticking out the front is just

a drawbar and coupler so the plow could be transported within a train. The

chimney is from a stove which heated the interior of the car.)

In the cab of the working plow, would be an experienced plow

operator or "pilot" - usually an experienced maintenance of way person who

knew all the physical features of the line. Do you see that orange thing

hanging down below the middle of the plow? I believe that is this plow's

air-operated "flanger". Using compressed air from the locomotive, it is lowered

as the plow is being pushed to clean the snow away from around the rail.

Snow becomes ice, and ice around your track structure creates all kinds of

problems, including derailments.

You need the pilot to be experienced because if

the flangers are lowered in the wrong place, they tend to rip up switches,

the centre "guard rails" on bridges, timbers at road crossings, timbers at

passenger stations, etc. Or the lowered flangers might just derail the whole

snowplow movement - locomotive and all.

Have you ever seen those trackside signs that look like two

eyes? On CN it's two white circles on a black rectangle. On CP the black

and white are reversed. Those are called "snowplow targets" and they remind

the snowplow pilot that flangers or plow side "wings" need to be drawn in

soon for an approaching obstruction.

Until the days of two-way radio in the 1960s, snowplow pilots

told the pushing locomotive crew what to do via a regular locomotive whistle

mounted on the plow. The rulebook has all sorts of rules which standardized

the whistle or air signal commands to start, stop, speed up, slow down, reverse.

It would have been an exciting job at higher speed because of all the things

the snowplow pilot had to think of.

Also consider what you see when plowing new snow, particularly in a storm. You don't

see the track. Because a train steers itself on its rails, the

snow could be one or two feet over the rail and as long as nothing goes wrong you

seem to travel magically "over" the snow and through the woods, tra la,

tra la. (With an 8000 ton CP Rail freight train rolling at 40 mph in a snowstorm

near White River, Ontario, you don't steer ... and you certainly don't slip

off the "road" into the ditch.)

For the snowplow pilot there can be lots of swirling snow to

see through when it is three feet over the rail. The crew back in the steam

locomotive would often see absolutely nothing outside except white. That's

why the snowplow pilot controls the movement : operating the train air

brake valve, and operating the snowplow's external "locomotive" whistle for

railway crossings and to communicate instructions to the locomotive engineer.

The late model de luxe CNR plow above even has metal heating elements on the snowplow cab

windows to help keep them as clear as possible.

The Reids join the Rotary Club

In the St. John's shops, the Reid Newfoundland Company did its own locomotive

overhauls. It also constructed a few locomotives using precision parts imported

from the big locomotive builders - like Baldwin in the US. These parts might

include pistons and cylinders, precision steam valves, and the linkages

which synchronized these parts.

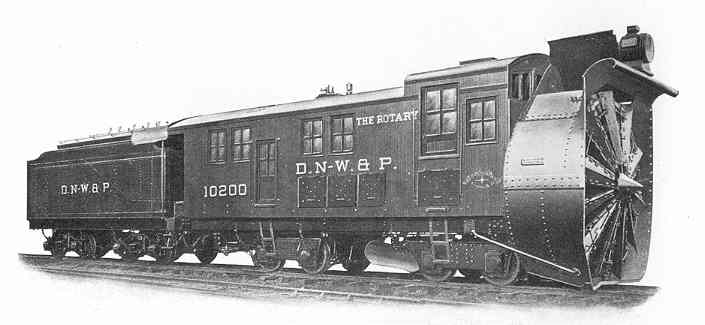

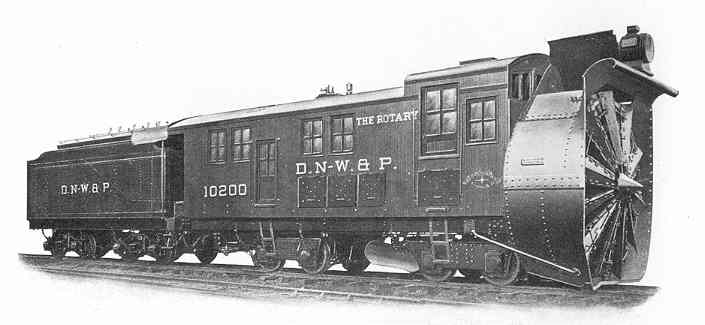

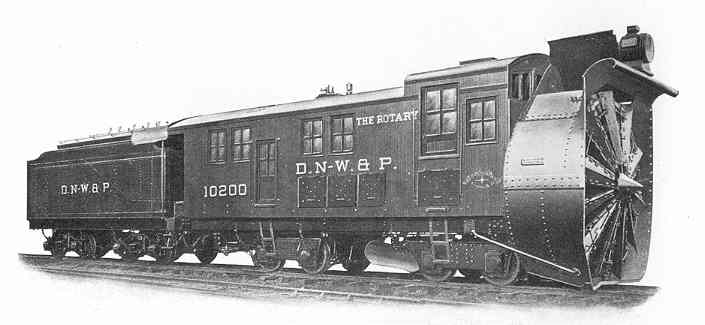

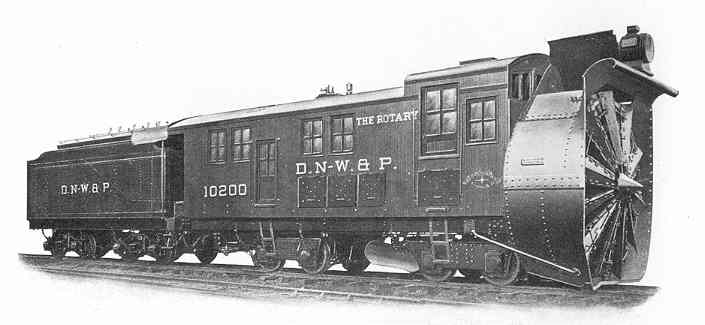

Also erected in the St. John's shops was at least one of these rotary

snowplows, complete with its own tender to carry fuel and water.

Question: With many more moving parts than a simple snowplow, why

did Newfoundland have three of these?

Answer: The snow got so deep around Gaff Topsail (and elsewhere) that

the snow walls beside the track were too high and the snow was too deep to

use snowplows like the orange one above. The output chute of the rotary is

just behind the headlight - considerably higher than the output height of

the wedge plow.

American Locomotive Company (Alco) rotaries similar to this were used

in Newfoundland by the Reids.

The huge dinosaur ancestor of driveway snowblowers, a key feature of the rotary

was the fact that the front surface being pushed into the snow face was virtually

all "live".

With the orange snowplow, the "snow on dead surface" resistance in deep

snow increases until the pushing locomotive starts to spin its wheels ... consider that

a human driveway shoveller can only push forward into a certain depth of snow on

a driveway before it packs and builds into a mass which can't be pushed anymore.

The rotary's "live" face is pushed only as fast as its powered scoop wheel can chew

up the snow and fling it out the output chute.

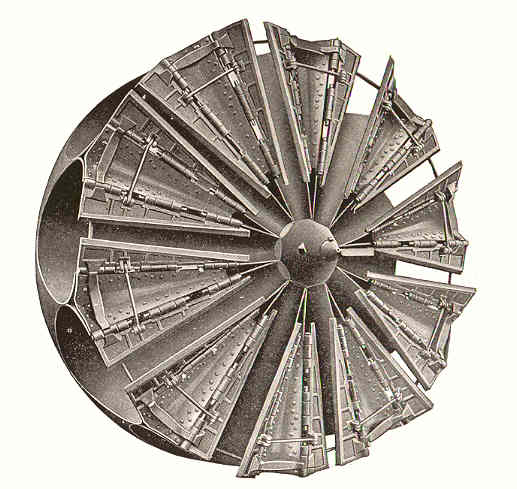

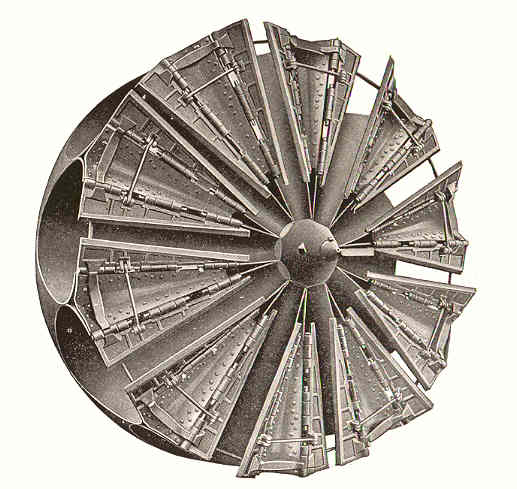

Below, you can see the blades of the rotating scoop wheel which would

chew into the snow face. As each individual empty cone-shaped chamber circled,

the blades would be filling it up with more and more snow. The scoop wheel housing's design (see above) ensures that

most of the snow cone ends are blocked by the scoop wheel housing

as the wheel rotates. But ... as soon as the wide end of a single "snow cone"

reached the output chute's opening, centrifugal force would send the snow

out of the scoop wheel and clear of the track in a graceful arc.

As we look at the scoop wheel from the front

of the plow, you can imagine that a counter-clockwise rotation would throw

the snow to the left. A clockwise rotation would empty the snow cones to the

right right side of the wheel as we look at it.

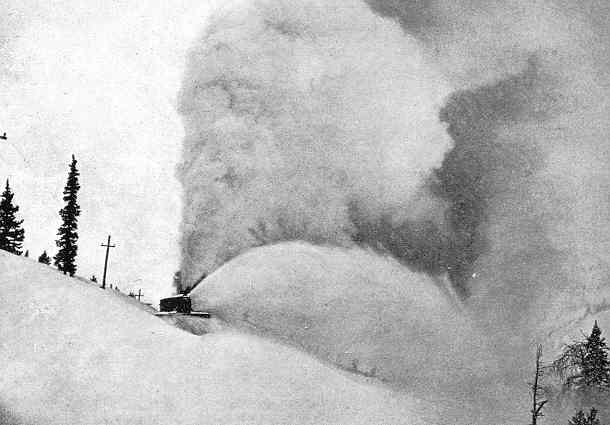

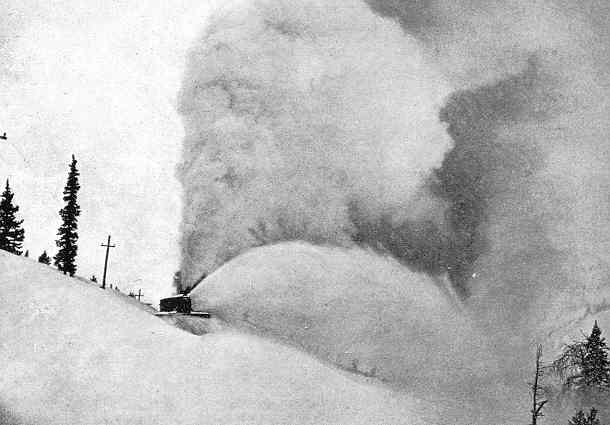

Below, a rotary is approaching the camera. The plume of thrown snow is dwarfed

by the smoke and condensing exhaust steam of the plow and the locomotive(s) behind it.

The rotary pilot in the cab of the plow would be watching the snow load

to be moved ahead of the train and listening to the chuffing exhaust of his

rotary and other telltale sounds. He would signal the locomotive to slow if the wheel was in danger

of stalling, or to speed up if the rotary could be worked more efficiently.

All that fluffy steam comes from water - in this type of slow heavy work rotaries and

locomotives used large amounts of water. In extreme cases, heavy wet snow mixed with falling rain ensured

very slow progress. But it was still better than shovelling by hand !

If the orange plow was used here in the location pictured below, it would be making a useless effort to

push the snow up hill. These photographs are not from Newfoundland.

In Newfoundland (and elsewhere), it was often advantageous to have a rotary

train with the locomotives in the middle and a rotary snowplow facing outward

on both ends. This operating detail suggests that they had some major problems with snow around

the Topsails and the last thing they wanted was to get a single rotary stuck

in the snow with no "backup" plan. It also eliminated the need to turn a single rotary to run back

through a heavy snowstorm or deep drifting ...

Checking the 1957 timetable above, there were 6 places to turn trains in

the 90 mile section which included the Topsails. They are indicated by the

symbol "Y" which crudely represents the path a train would follow to turn

around.

As single snowplows and single rotary snowplows could only be useful in one

direction, having multiple places to turn was handy. It enabled plows to

make repeated passes where the snowfall or drifting was the heaviest. It

also made relief quicker when regular trains became stuck and needed to be

rescued as soon as possible. Passenger trains sometimes got stuck for

days in Newfoundland.

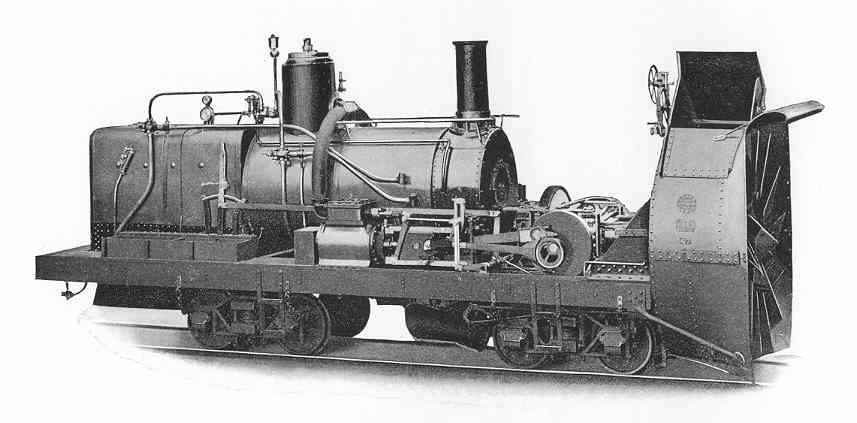

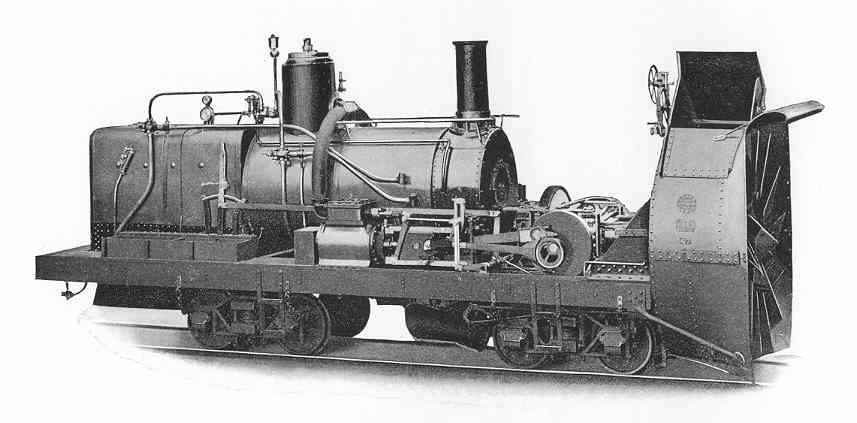

If you haven't before, why don't you take a peek inside a steam-driven rotary

snowplow ...

Before large diesel, and diesel-electric powerplants were available to spin

the big scoop wheel, designers in the late 1800s and early 1900s used steam

power.

The rotary snowplow is propelled forward by a regular locomotive,

so the square firebox and the round boiler extending out to its right are

there specifically to drive the scoop wheel. The plow could never propel itself.

Pipes coming down on both sides of the boiler from the barrel-like steam dome (at the

top) carry steam to the cylinders where the steam's expansive power alternately pushes

on one of the two pistons - one on each side. Because the fuel is burned outside the

piston, this is an external combustion engine.

In the little

box above the piston are valves which control the flow of the expanding gas(es) in and out of the cylinder like an automobile's

engine valves do. Located between the little box above the cylinder and the scoop wheel, are all the linkages

which essentially control the direction, speed and power of the scoop wheel.

You can also see the driveshafts responsible for converting the reciprocating

motion of the piston, to transverse rotation, to longitudinal rotation ...

or as I would say it: in and out ... becomes round and round across

to the centre of the plow ... becomes round and round forward to the centre

of the scoop wheel ... which spins like a big pinwheel.

From reading accounts of rotary operation it seems that the main drive shaft was weakened to break before major damage

was done to other mechanisms. Working around Gaff Topsail, they had an efficient

routine for changing out a broken drive shaft in the middle of a snow storm.

Let's face it, they HAD to be good at this - it was a pretty tough neighbourhood to be stranded in.

And behind the second wheel of the plow, you can see a big healthy flanger

(the scoopy-looking thing) which would be raised and lowered by air or steam

pressure. The lowered flanger would scoop the snow away from inside the rail

and plow it over the rail and off to the outside of the track structure where it couldn't bother anyone ever again.

Oh, and right behind the scoop wheel housing at the discharge chute,

you can see a spoked wheel ? That is where the pilot stood or sat. Of course

they would be in a cab, shielded from all the moving parts, but the heat,

noise and vibration would probably start to get to them on 12-24 hour long missions to keep the line open.

In case you ever want to buy a steam-powered rotary snow plow ...

Here is a sampling of some of the procedures to follow :

- "When within fifty feet of a bank, the pilot should signal the engineer

on the Rotary to go ahead, which should be the signal for him to open his

throttle and regulate the speed of the wheel with his reverse lever to about

150 revolutions per minute."

[As well as each locomotive having an engineer and fireman, the

rotary also has an engineer and fireman ... the fireman to produce steam

and the engineer to operate the big scoop wheel according to the pilot's

instructions.

Rotary wheel spinning instructions : via internal air whistle from the pilot.

Locomotive(s') movement instructions : via the rotary's external locomotive whistle from the pilot.]

- "When within about five feet of the bank, the pilot should give the

second signal for the Rotary to come ahead ; and the engineer should then

increase the speed of the wheel.

- When the Rotary strikes the snow, the pilot should signal the pusher ahead.

- If he finds the Rotary can stand the full power of the pusher, he

should give a second signal to come ahead, which should mean for the engineer

on the pusher to put on full power.

- If the pusher is crowding the Rotary too much, the signal should be

given to the engineer of the Rotary to increase the speed of the wheel.

- In case the pusher is still crowding the Rotary, the pilot should apply the air brakes quickly to check the pusher.

- If unable to hold the pusher with the brakes, he should give the

signal to the engineer of the pusher to shut off, who should respond instantly

to avoid stalling the Rotary.

- When within about ten feet of the end of a drift, the pilot should

give the engineer on the Rotary the signal to slow down ; and, when almost

out of the bank, the signal to shut off - which the engineer on the Rotary

should understand to mean to slow down to the normal speed of the wheel."

Summing up the key details ...

Summing up the key details ...

Due to Newfoundland's climate and a government-prescribed

route through the Topsails area, the Reids' Newfoundland railway and its successors

had local snowfalls which rivaled those in the Rockies and Selkirks for

their ability to stop operations during the winter season.

Consequently, the Reids obtained, and sometimes their shops in St. John's, assembled the "state of

the art" technology for deep snow removal : the Rotary Snowplow. It was not

self-propelled - it was pushed along by regular steam locomotives.

Generally based in Corner Brook and Bishops Falls - the railway centres

bracketing the Topsails - the rotaries were used when regular push plows

could no longer keep the line open.

The rotary snowplow equipment above would have a crew of three.

A fireman

and engineer operated the enclosed steam engine which powered the big scoop wheel.

The rotary pilot occupied the cab immediately behind the scoop wheel. Like

a ship's captain, his remote commands governed all aspects of the rotary train's operation

(2 engineers and 2 firemen). The rotary plow pilot controlled the train air brakes.

With all the flying snow, smoke and steam, the pilot was the only crew member who could see the buried right of way ahead.

* * *

Traffic control was based in either St. John's or Bishops Falls during

this era.

Through local railway telegraph operators, dispatchers in these two locations

received information on the local snow conditions.

The dispatchers issued the appropriate

orders to operate plows and/or regular traffic at various points along the line ... and the Topsails area demanded much of their attention in winter.

In extreme cases, Newfoundland plow trains were operated with simple

push plows or rotaries on both ends so turning would not be necessary. The

abundance of turning locations (wyes) in the Topsails region suggests

that it was handy to have plenty of turning options when operating plow trains

with a plow on only one end.

As steam locomotives became more powerful and diesel locomotives became

available, more and more Newfoundland snow clearing could be handled with push plows.

The steam rotaries probably did not survive Newfoundland Railway dieselization

in the 1950s.