Coal Mining in Cape Breton

I grew up reading 'Sydney' on

the rails of the nearby CNR railway ... and 'Algoma' on the rails of

the CPR. In 1990 at Coldwell, Ontario, it read 'Nippon' on the rails

which the CPR was about to install.

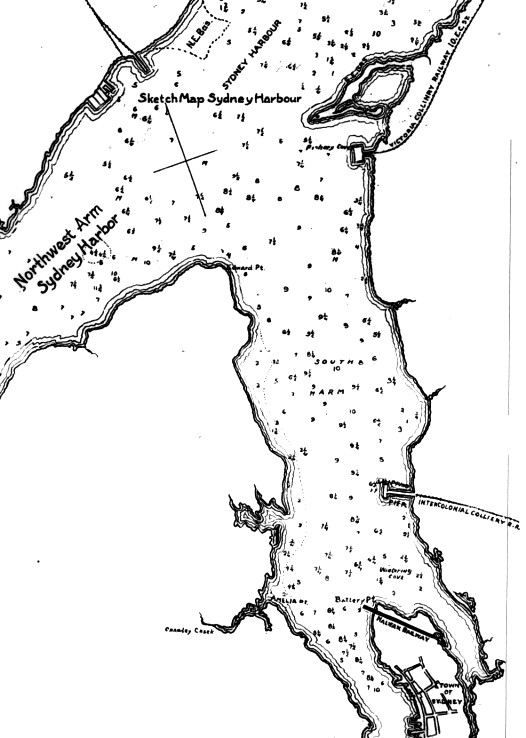

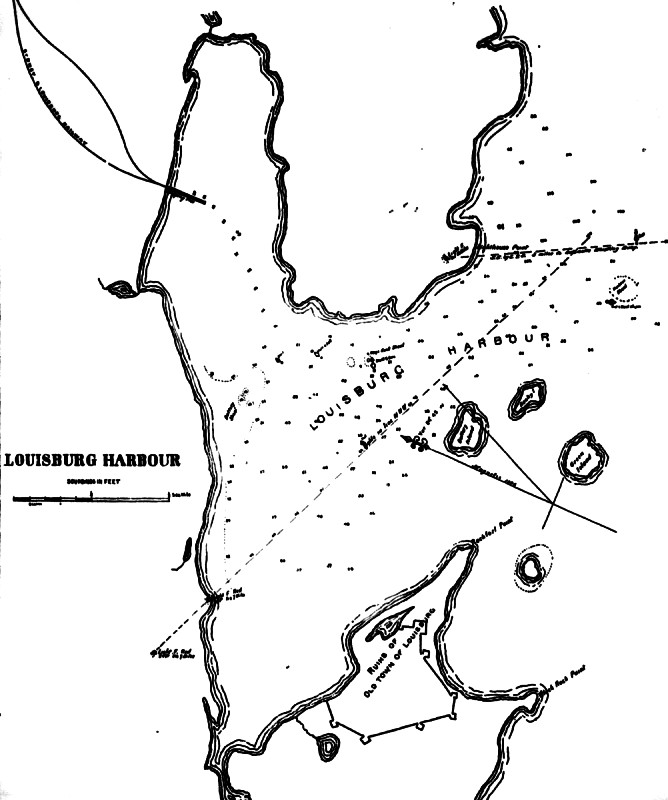

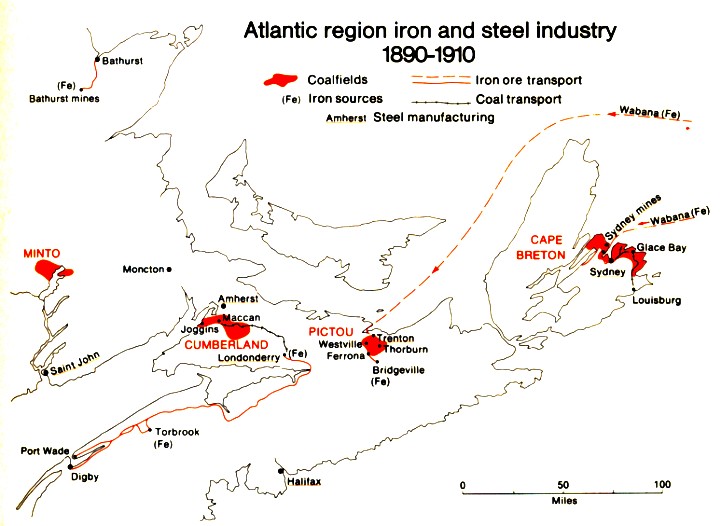

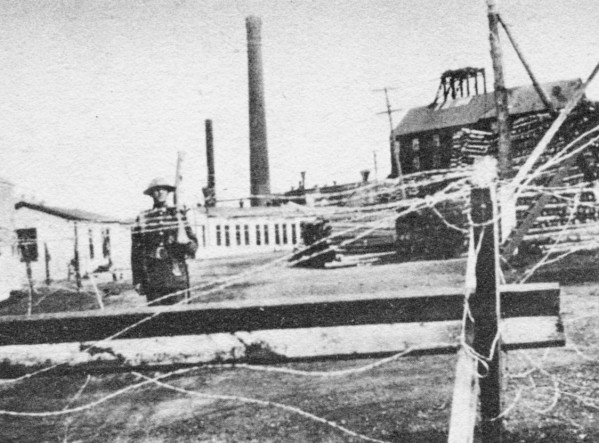

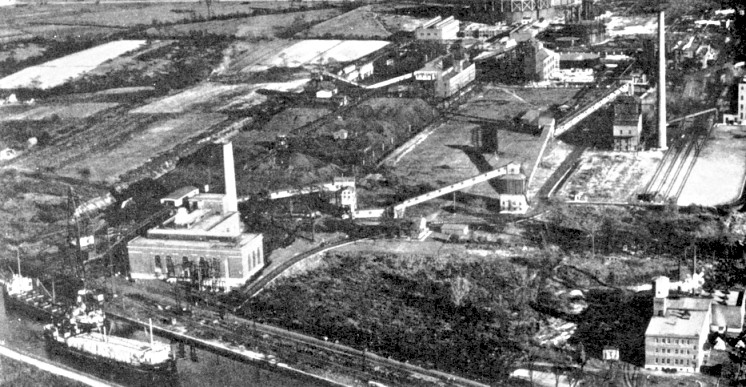

In 1980 and 1988, during vacations to the Atlantic Provinces, the unique industrial heritage of Cape Breton around Sydney provided an interesting lesson in Canadian history for us. This page is an attempt to explain some aspects of the pursuit of this ancient mineral resource from the beginning.

In 1980 and 1988, during vacations to the Atlantic Provinces, the unique industrial heritage of Cape Breton around Sydney provided an interesting lesson in Canadian history for us. This page is an attempt to explain some aspects of the pursuit of this ancient mineral resource from the beginning.

This page has become so large,

that I have attempted to lessen the misery of visitors by adding the

table of contents below, with links back and forth within the page.

Most readers will probably be content to simply have a quick look at the sections which interest them.

Introduction

Introduction Early collieries in Britain

Early collieries in Britain Mine ventilation

Mine ventilation A Canadian steam powered colliery railway in the 1830s

A Canadian steam powered colliery railway in the 1830s George Monro Grant describes Cape Breton in 1882

George Monro Grant describes Cape Breton in 1882 Happy Mine

Happy Mine Cornish pumping engine

Cornish pumping engine Engineering, Scottie here.

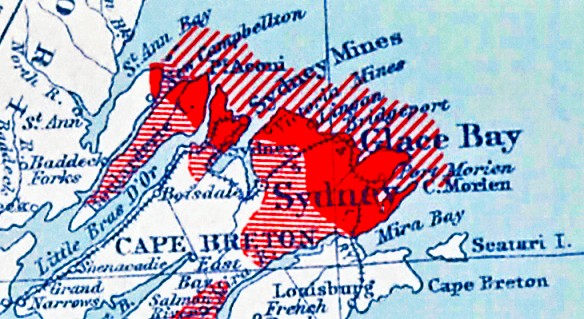

Engineering, Scottie here. Coal near Sydney

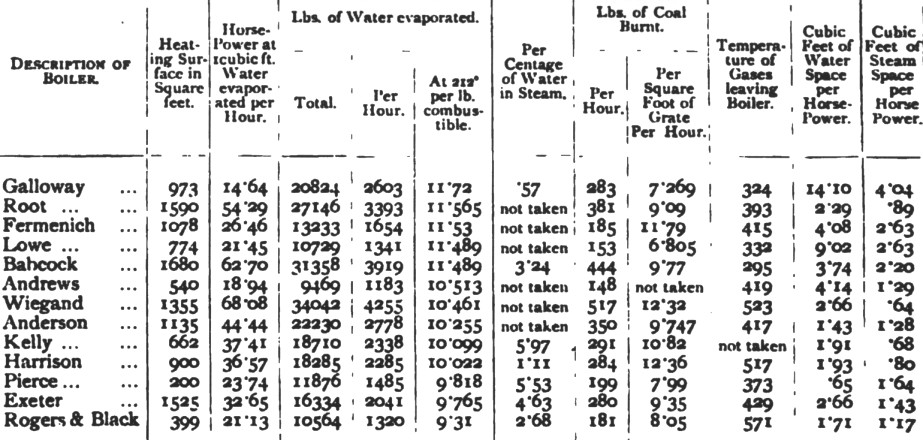

Coal near Sydney Get the most from your mine!

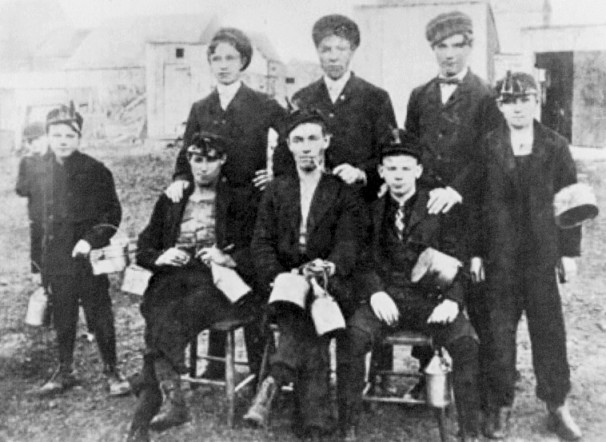

Get the most from your mine! Boys in the mines

Boys in the mines Endless rope haulage & Tippler work

Endless rope haulage & Tippler work Technology in Nova Scotia mines

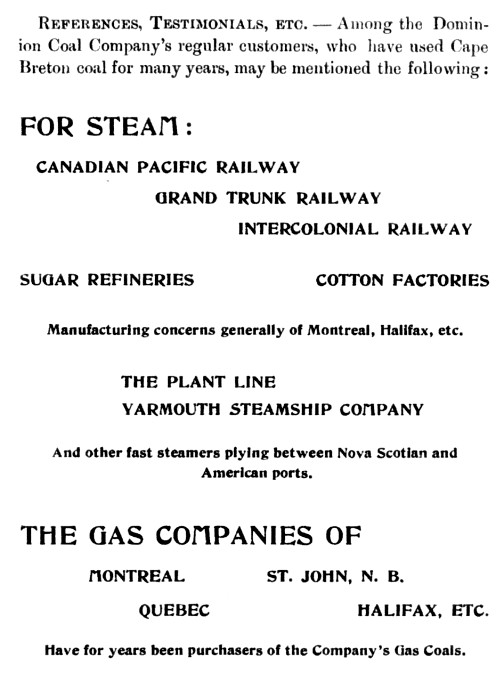

Technology in Nova Scotia mines Some uses of coal in the early 1900s

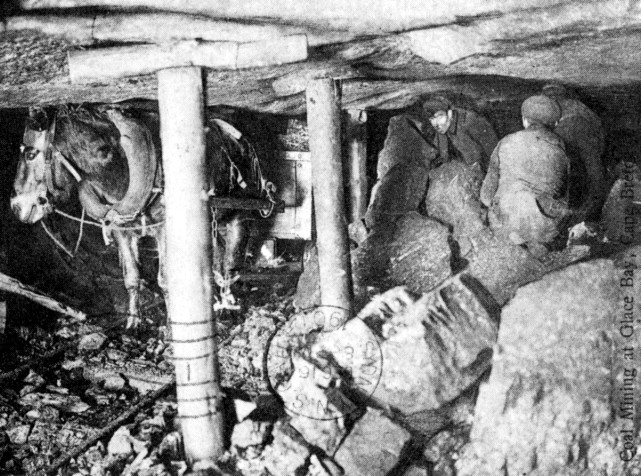

Some uses of coal in the early 1900s Glace Bay

Glace BayIntroduction

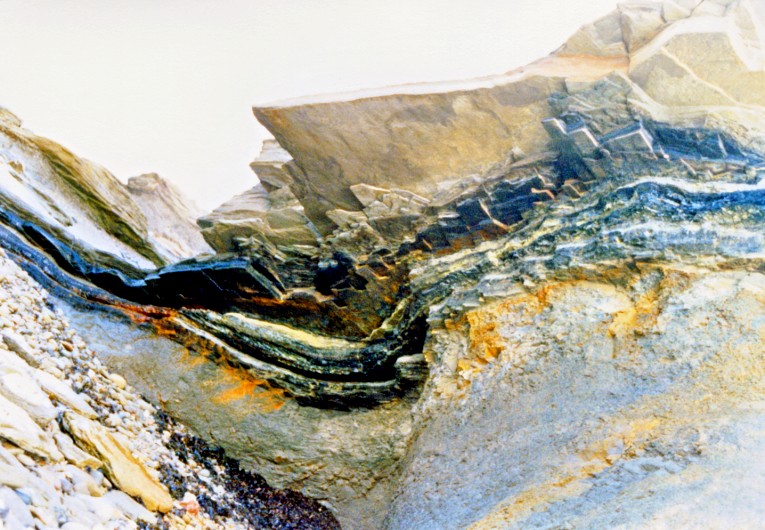

The seashore at Glace Bay, Cape Breton, Nova Scotia in 1980.

One of Canada's few areas of 'coal measures' ... seen during a vacation trip.

Looking up from the same shoreline to representative sedimentary rocks containing a little iron and a little coal.

Coal is not a uniform substance of uniform quality for burning ... unlike ... a manufactured 'sawdust log'.

A great deal of practical experience and 'nature study' over time was necessary to understand how to effectively exploit this natural resource.

Coal was essential in creating the 'western civilization' which many of us inherited ...

It reminds us of other climates and now obsolete life forms which were here long before us.

If history is any guide ...

The geological record of coal will exist long after the planet bids our civilization farewell.

* * *

Often shale is found just above

coal. Layers of clay are often found just below coal seams.

When ancient people (like the original 'Britons') burned coal it was often found as sea coal ... which had been released by the power of the waves from the shore ... 'hey, this black rock burns!'

People also found this mysterious rock in simple surface outcroppings. Hacking away at the outcroppings they would 'mine' as much as they could.

Shapes in the coal looked like plants people had never seen before ... they gradually developed theories about where coal came from.

Much more important than 'theories' to utilitarian people concerned about comfort or trade was ... where could more of this really excellent fuel be found ... should they look for other 'plant picture rocks'? Could coal be found everywhere (in Britain) just be digging deep enough?

To spoil the surprise ... coal was formed during the Carbon-iferous period roughly 360 to 300 million years ago. Massive amounts of plant material with lots of lignin (lignin is barky stuff) died and fell down.

One explanation for coal's subsequent formation is that nothing had evolved to digest all this lignin so it was very well preserved - just like Dick Clark.

This is what is so special and precious about coal ... it is sedimentary or metamorphic rock made out of STP - Specially Treated PlantMaterial.

It has lots of 'big carbon' molecules which had no useful purpose in life ... until we thoughtfully came along and started pyrolyzing and oxidizing them ... i.e. turning rocks into air.

One aspect of atmospheric science linked to this Carbonosaurus Period is that with all this lignin going into proto-coal carbon-sinks ... the atmosphere had 'too much' oxygen in it. Without even doing cardio twice a week ... super-sized, inefficient animals could thump around the planet without even getting winded!

So coal is laid down in layers like other sedimentary rocks ... but unlike the particles forming shale (clay) or sandstone ( ... sand! ... geez!) ... coal is made of old plant material which has received some kind of protection from being completely broken down by micro-organisms and weathering. Maybe the decaying swamp was acidic ... maybe not enough 'bugs' could digest it at that time in geological history ... maybe it was effectively sealed away under other sediments. Some kinds of coal (e.g. anthracite coal) is more accurately a 'metamorphic rock' as its original sedimentary characteristics have been altered by great heat and/or great pressure.

As society demanded more and more coal, British miners devised all sorts of techniques and technologies to obtain it. As a layer of rock lies around for 300 million years, it is subject to all the effects of plate tectonics ... and forces above the lithosphere such as weathering, glaciation, and flooding.

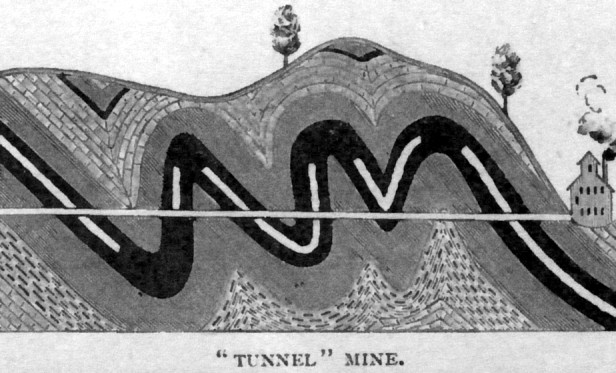

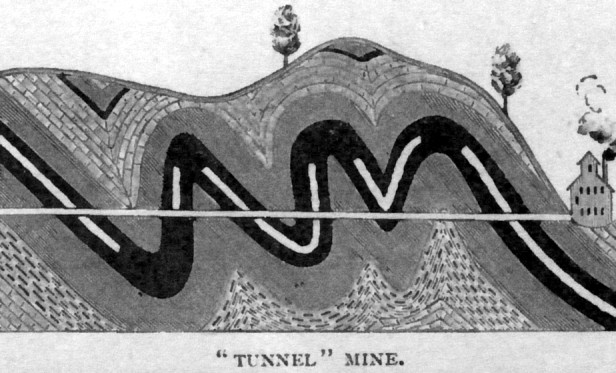

Much of the 'coal measures' in Britain had been subject to all sorts of scrunching by tectonic plates coming together. So instead of a nice flat thick bed of coal like a pan of brownies ... British coal miners often found irregular coal beds sloping almost vertically ... or discontinuous faulted beds with some sections up and some sections down ... or folded coal seams which took on shapes like the letter 'W'.

When ancient people (like the original 'Britons') burned coal it was often found as sea coal ... which had been released by the power of the waves from the shore ... 'hey, this black rock burns!'

People also found this mysterious rock in simple surface outcroppings. Hacking away at the outcroppings they would 'mine' as much as they could.

Shapes in the coal looked like plants people had never seen before ... they gradually developed theories about where coal came from.

Much more important than 'theories' to utilitarian people concerned about comfort or trade was ... where could more of this really excellent fuel be found ... should they look for other 'plant picture rocks'? Could coal be found everywhere (in Britain) just be digging deep enough?

To spoil the surprise ... coal was formed during the Carbon-iferous period roughly 360 to 300 million years ago. Massive amounts of plant material with lots of lignin (lignin is barky stuff) died and fell down.

One explanation for coal's subsequent formation is that nothing had evolved to digest all this lignin so it was very well preserved - just like Dick Clark.

This is what is so special and precious about coal ... it is sedimentary or metamorphic rock made out of STP - Specially Treated PlantMaterial.

It has lots of 'big carbon' molecules which had no useful purpose in life ... until we thoughtfully came along and started pyrolyzing and oxidizing them ... i.e. turning rocks into air.

One aspect of atmospheric science linked to this Carbonosaurus Period is that with all this lignin going into proto-coal carbon-sinks ... the atmosphere had 'too much' oxygen in it. Without even doing cardio twice a week ... super-sized, inefficient animals could thump around the planet without even getting winded!

Those were the Good Old Days.

Early Collieries in Britain

So coal is laid down in layers like other sedimentary rocks ... but unlike the particles forming shale (clay) or sandstone ( ... sand! ... geez!) ... coal is made of old plant material which has received some kind of protection from being completely broken down by micro-organisms and weathering. Maybe the decaying swamp was acidic ... maybe not enough 'bugs' could digest it at that time in geological history ... maybe it was effectively sealed away under other sediments. Some kinds of coal (e.g. anthracite coal) is more accurately a 'metamorphic rock' as its original sedimentary characteristics have been altered by great heat and/or great pressure.

As society demanded more and more coal, British miners devised all sorts of techniques and technologies to obtain it. As a layer of rock lies around for 300 million years, it is subject to all the effects of plate tectonics ... and forces above the lithosphere such as weathering, glaciation, and flooding.

Much of the 'coal measures' in Britain had been subject to all sorts of scrunching by tectonic plates coming together. So instead of a nice flat thick bed of coal like a pan of brownies ... British coal miners often found irregular coal beds sloping almost vertically ... or discontinuous faulted beds with some sections up and some sections down ... or folded coal seams which took on shapes like the letter 'W'.

Early coal pits were simply ...

pits. They took the shape of bells as the important coal layer at the bottom was

harvested down and out to the point of causing the walls of the pit to collapse.

There was a general expectation by property owners that the previous bell pit would be

filled in by the miners before starting the next.

Then the pits began to evolve into 'mines' as we know them ... a single shaft was dug to reach the level of the coal deposit and tunnels were picked and shovelled ... radiating from this subterranean base to obtain as much coal as possible from the single deep shaft. Woven baskets, wheeled vehicles, and eventually vehicles travelling on rails, were used to slide the coal back to the vertical pit. Back at the pit or shaft ... ladders were used by workers to carry baskets of coal to the surface.

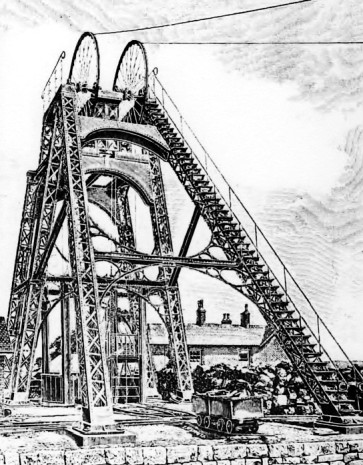

Eventually tubs ... hoisted by ropes ... which ran through pithead or 'headframe' pulleys ... were hauled up by horses working on the surface.

The definition of 'horsepower' (550 foot-pounds per second) as applied to engines or motors, is derived from horses lifting coal out of the pits ...

Miners wanted to know ... to dead-lift people, water, and coal straight up mineshafts ... could a particular steam engine provide the performance they required?

Then the pits began to evolve into 'mines' as we know them ... a single shaft was dug to reach the level of the coal deposit and tunnels were picked and shovelled ... radiating from this subterranean base to obtain as much coal as possible from the single deep shaft. Woven baskets, wheeled vehicles, and eventually vehicles travelling on rails, were used to slide the coal back to the vertical pit. Back at the pit or shaft ... ladders were used by workers to carry baskets of coal to the surface.

Eventually tubs ... hoisted by ropes ... which ran through pithead or 'headframe' pulleys ... were hauled up by horses working on the surface.

The definition of 'horsepower' (550 foot-pounds per second) as applied to engines or motors, is derived from horses lifting coal out of the pits ...

Miners wanted to know ... to dead-lift people, water, and coal straight up mineshafts ... could a particular steam engine provide the performance they required?

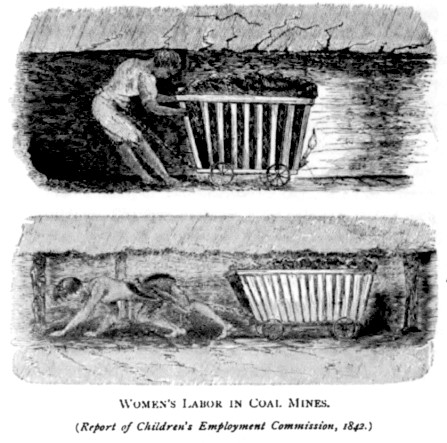

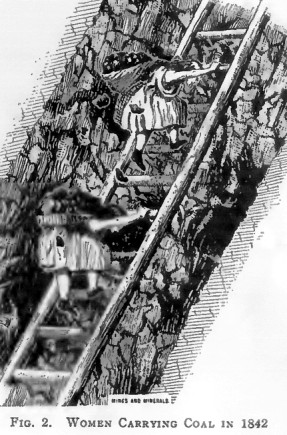

from The History and Description of Fossil Fuel, circa 1850

'Children

began their life in the coal mines at five, six or seven years of age.

Girls and women worked like boys and men, they were less than half

clothed, and worked alongside of men who were stark naked. There were

from twelve to fourteen working hours in the twenty-four, and these

were often at night. Little girls of six or eight years of age made ten

to twelve trips a day up steep ladders to the surface, carrying half a

hundred weight of coal in wooden buckets on their backs at each

journey. Young women appeared before the commissioners [investigating

mine conditions in Britain], when summoned from their work, dressed

merely in a pair of trousers, dripping wet from the water of the mine,

and already weary with the labor of a day scarcely more than begun. A

common form of labor consisted of drawing on hands and knees over the

inequalities of a passageway not more than two feet or twenty-eight

inches high a car or tub filled with three or four hundred weight of

coal, attached by a chain and hook to a leather band around the waist.'

Legislation was passed in Britain in 1842

prohibiting women and boys under thirteen years of age from working in

mines ... as well as regulations for lighting, hours of work,

ventilation, safety, and licensing of engineers. There were still

plenty of things which would continue to threaten human life

underground throughout the history of coal mining ...

- Sometimes, in the small, cramped mining chambers, a miner would unexpectedly trigger a massive ceiling collapse which would kill him.

- An adjacent pocket of water or an underground watercourse could suddenly fill the lower works, drowning the miners.

- Originally, sudden deaths without visible physical trauma were thought to be caused by evil spirits or goblins. Later they were categorized by descriptive terms which were retained even after the chemistry behind the deaths was finally understood ...

- Explosions

were caused by 'Fire Damp' - methane ('light carburetted hydrogen') often mixed with suspended coal dust.

- Suffocations were caused by 'Black Damp' or 'Choke Damp' ... gases such as carbon dioxide ('carbonic acid gas').

- Suffocations could also be caused by 'After Damp' ... which followed a 'Fire Damp' explosion which had used up the oxygen.

Using whale oil lamps usually attached to their clothing as they travelled, miners used picks, shovels and wedges to break the rock and coal into manageable pieces. Blasting powder was also used with a powder-filled straw serving as a fuse.

Clearing accumulated water seepage from the mines was such a persistent and universal problem that it led to the invention of the first (atmospheric) steam engines.

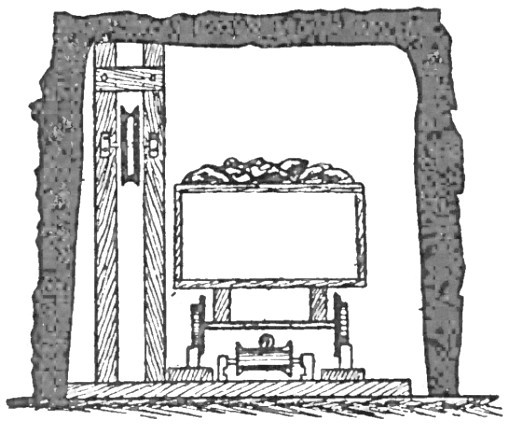

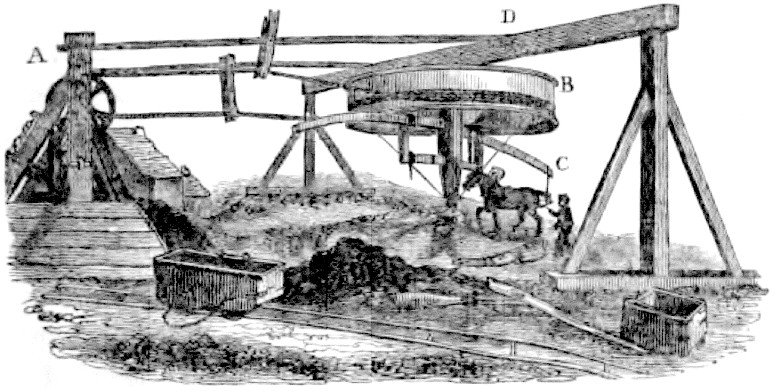

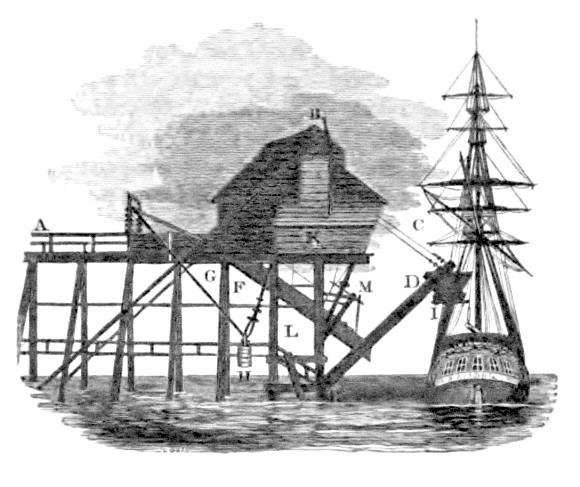

An early reversible mineshaft hoisting device circa 1840

A mine headframe and pulley ... are located at 'A'.

The hoisting rope is taken up on the reel at 'B'.

A horse operating the windlass (or 'gin') is at 'C'.

To lower items or miners, the horse would be reversed and walked in a clockwise direction.

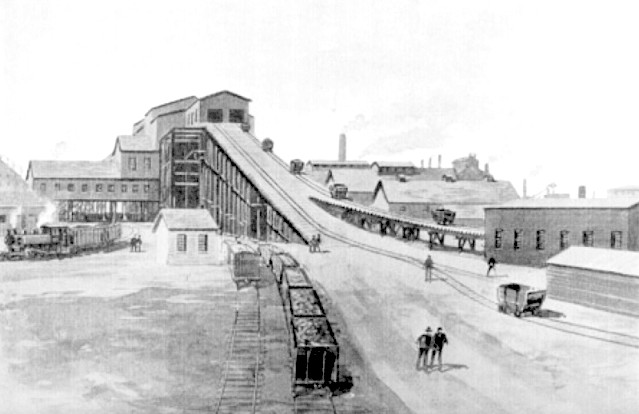

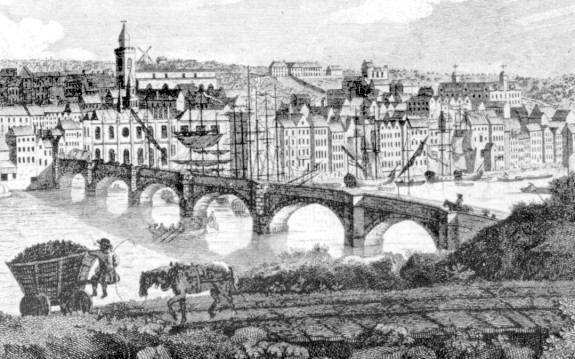

Newcastle-upon-Tyne in 1783 - an important coal centre dating back to the 1400s.

Before the Industrial Revolution

employed steam power, various railway technologies were already being

used to increase efficiency. Usually, the mission was to get coal from

a mine ... to a canal or sea transport at a lower elevation. At water

level, sailing ships or common coal barges ('keels') would be used for

transportation. The coastal shipping of coal provided basic training for many

sailors who would go on to crew British warships or merchant vessels on

the high seas - sometimes, whether they wanted to or not (when the Press Gangs were in town).

The design of the coal wagon above (like the keel barges) was generally a standard design which evolved slowly. Copies of traditional coal wagons like this are also shown in some early coal mining photos from Nova Scotia. Many miners and mining engineers came to Cape Breton from Britain ... and brought their usual technologies with them. Above, putting the cart before the horse, the driver is SITTING on the mechanical brake lever (called a convoy) to control speed down the grade as he smokes his pipe. On steeper parts of the run downhill, the horse can provide additional braking force ... the driver hopes. The brake can also overheat - sometimes setting the wooden cart on fire. Beyond the bridge, you can see a keel or two on the river.

The design of the coal wagon above (like the keel barges) was generally a standard design which evolved slowly. Copies of traditional coal wagons like this are also shown in some early coal mining photos from Nova Scotia. Many miners and mining engineers came to Cape Breton from Britain ... and brought their usual technologies with them. Above, putting the cart before the horse, the driver is SITTING on the mechanical brake lever (called a convoy) to control speed down the grade as he smokes his pipe. On steeper parts of the run downhill, the horse can provide additional braking force ... the driver hopes. The brake can also overheat - sometimes setting the wooden cart on fire. Beyond the bridge, you can see a keel or two on the river.

The 'staith' illustration above

shows

features which allow the specialized coal pier to load both sailing

ships and keels. The chute

above 'L' could be used to load the low-slung keels if a mine wagon was

emptied above the letter 'G' - 'L' is a 'trunk staith' . A loaded wagon

weighed 2

to 3 tons. "When a waggon lets fall its contents down one of these

spouts, the noise at a distance very much resembles a clap of thunder".

This kind of rough treatment would be unacceptable for the lowest

quality

coals, as they would turn into unmarketable dust.

To load the sailing ship, the loaded wagon in the cradle at ' I ' ... is lowered in an arc from the pier's cabin ... by the boom 'D'. To maintain control, the staith operator brakes the reel hidden from us inside the cabin ... which spools the ropes 'C' as the heavy wagon descends over the sailing ship's hold. Often a staith labourer would ride down with the cradle and coal wagon, tripping the wagon's trap door and releasing the coal into the ship's hold.

Unloaded, the coal wagon is lighter ... and the attached counter-weight of cast iron plates 'H' raises the boom and the empty wagon to their starting position.

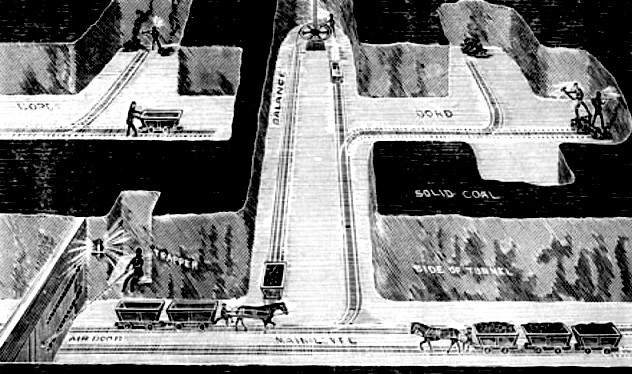

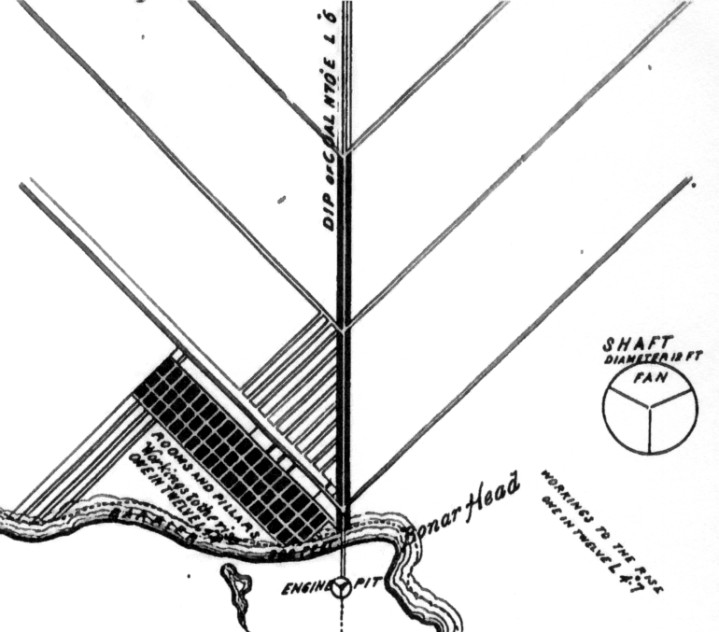

In the 1840 'horse gin' hoist illustration above, a pit with a vertical shaft was depicted.

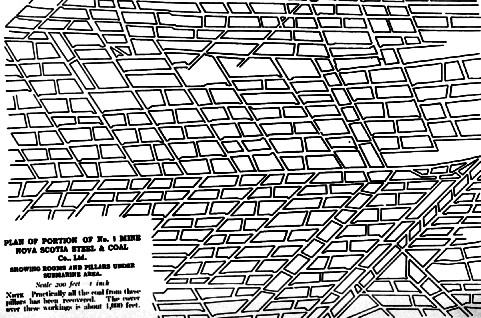

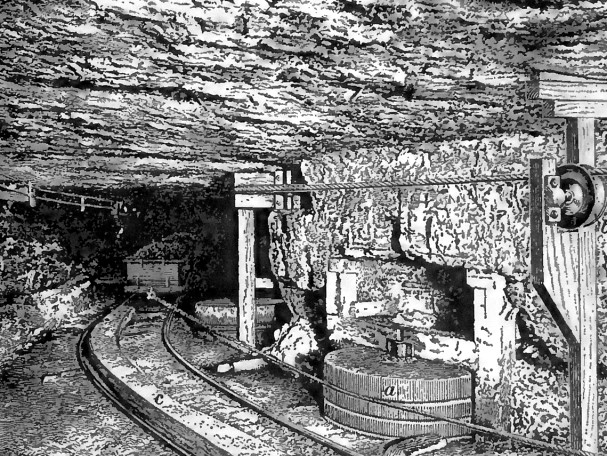

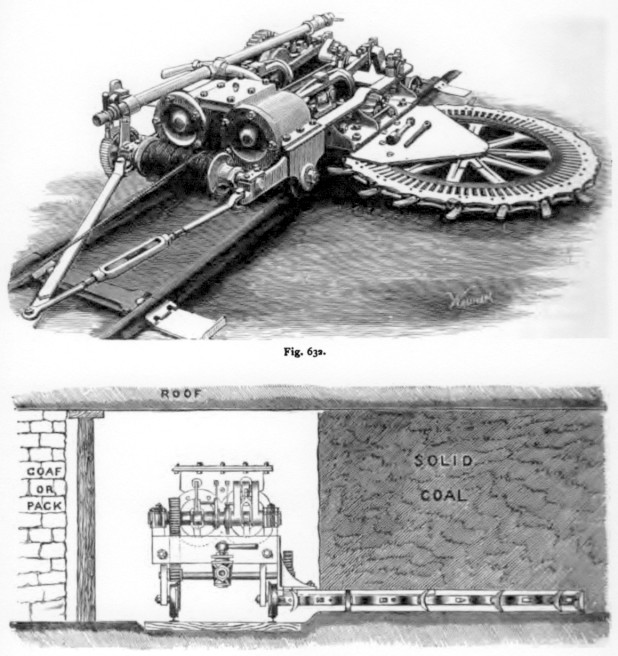

As this 1880s textbook suggests, many additional techniques had been worked out to tunnel out coal however it lay.

After the bell pit design was abandoned,

a coal mine became a complex piece of architecture ...

with multiple systems engineered and installed to protect life and efficiently remove as much coal as possible.

Furthermore, a mine was only 'complete' once further architectural change yielded no further financial reward.

As architecture, a coal mine provided the 'ultimate perpetual renovation project'.

Mine VentilationTo load the sailing ship, the loaded wagon in the cradle at ' I ' ... is lowered in an arc from the pier's cabin ... by the boom 'D'. To maintain control, the staith operator brakes the reel hidden from us inside the cabin ... which spools the ropes 'C' as the heavy wagon descends over the sailing ship's hold. Often a staith labourer would ride down with the cradle and coal wagon, tripping the wagon's trap door and releasing the coal into the ship's hold.

Unloaded, the coal wagon is lighter ... and the attached counter-weight of cast iron plates 'H' raises the boom and the empty wagon to their starting position.

In the 1840 'horse gin' hoist illustration above, a pit with a vertical shaft was depicted.

As this 1880s textbook suggests, many additional techniques had been worked out to tunnel out coal however it lay.

After the bell pit design was abandoned,

a coal mine became a complex piece of architecture ...

with multiple systems engineered and installed to protect life and efficiently remove as much coal as possible.

Furthermore, a mine was only 'complete' once further architectural change yielded no further financial reward.

As architecture, a coal mine provided the 'ultimate perpetual renovation project'.

Out of necessity, mine

ventilation rapidly became quite a science.

Imagine a simple groundhog burrow with 'a means of egress' at each end ...

If one has access to the atmosphere at each end of a tunnel ... simply pushing or pulling the air through the tunnel at one end would be adequate for good ventilation. The air will take the shortest course to equalize its pressure.

... so a healthy and efficient groundhog (probably after an engineering consultation with a beaver) would erect an air scoop on the windward entrance of the burrow to funnel the wind through.

Coal mines are irregular as their tunnels follow the usually disrupted pattern of the coal bed. Ideally, miners dig out only coal as they tunnel ... with a natural 'ceiling' and 'pavement' of 'worthless' rock strata left undisturbed.

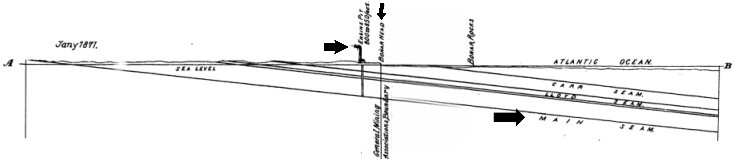

The luxury of an opening on each end is not possible if the pit is very deep (e.g. Springhill, Nova Scotia) or the pit follows the coal seam out under the sea (e.g. Sydney and Glace Bay, Nova Scotia).

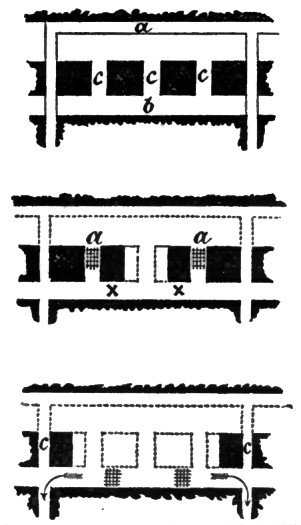

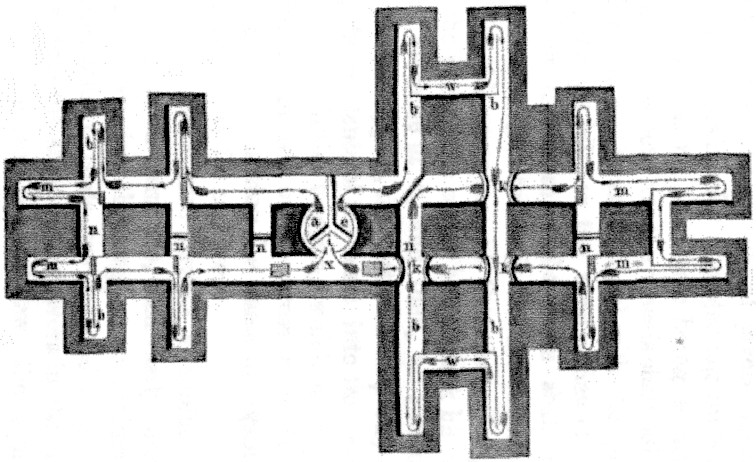

Coal mine ventilation is like a maze puzzle which can be solved with a pencil ... once the walls and baffles are put in place.

In the 1850s model mine pictured below - the ventilation system is is powered by two coal furnaces - the two grey rectangles on either side of 'x'.

"The furnace resembles an ordinary

old-fashioned fire-place with stout grate bars. It is constructed near

the foot of an opening into the mine, and furnished with a smoke-flue

built of brick. This flue leads into the air passage of the surface

opening at some distance above the floor of the mine. The volume of

heat from this furnace passing into the airway creates and maintains a

strong upward air current. In some mines the furnace is built at the

foot of an air shaft a long distance from the main opening, thus making

it an upcast air shaft. By the continued use of a huge fire in this

furnace a powerful current of air may be put and continued in motion,

but it is found an expensive way of 'raising the wind' and the system is

rapidly giving place to the rotary steam fan."

'The Springhill Colliery Disaster', 1891

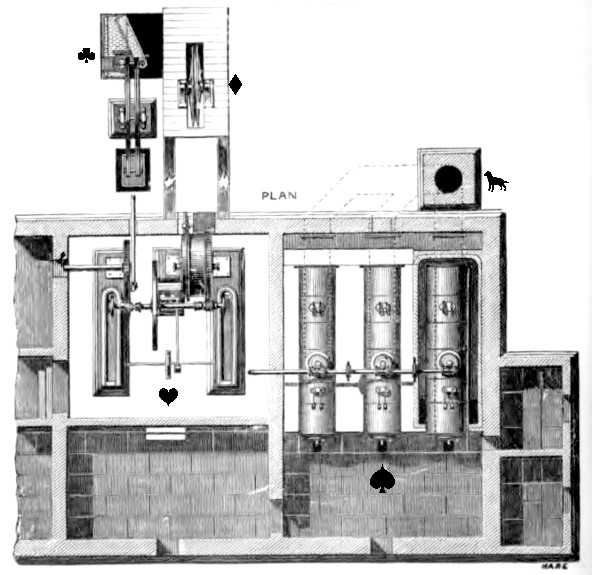

Diagram, ventilation model circa 1850.

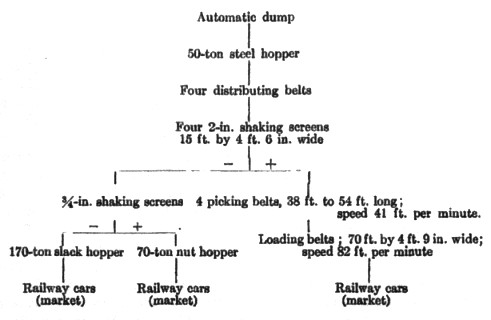

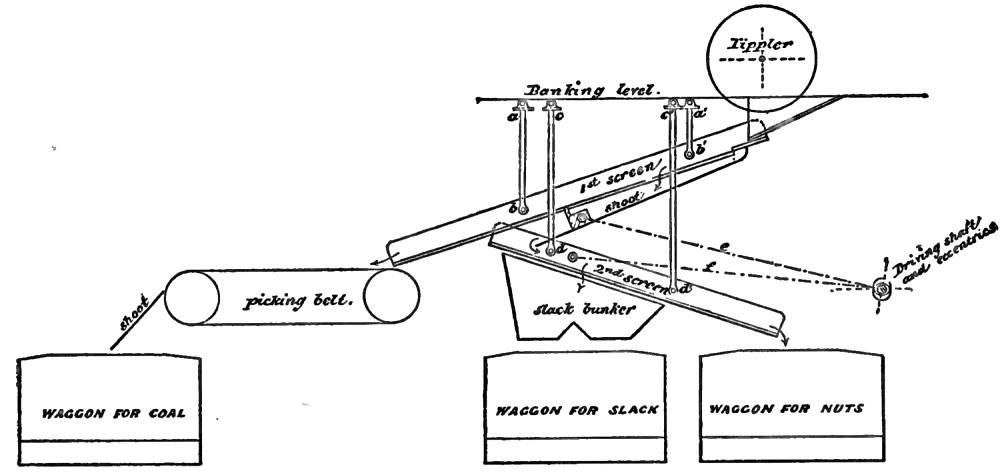

| x - Chimney (upcast) for the two furnaces - shown as grey rectangles on either side. a and e - Downcast air shafts which are also used to move miners, supplies and coal. b - 'Boards' or galleries where active mining is taking place in the transverse direction - relative to the coal seam. k - Arches which allow the air to pass over its former course. m - 'Winning headways' are passages which head in the main direction of the coal along the seam's main axis. n - Stentings between the double headways. w - Walls or passages between the boards at the end of each pillar - 'brattice'. Pillars - the columns of coal left in place to support the mine structure. Pillars prevent crushing by the intense pressure which may be unleashed when the coal deposit is hollowed out - usually pressure upward from the floor or downward from the ceiling. The square areas between the two main headways are examples of pillars required to keep the floor and ceiling from coming together. Robbing (the pillars) - a calculated but dangerous practice commonly used near the end of the life of a mine section. The supporting pillars of coal are partially chipped away until the ceiling begins to collapse. As you would expect, this begins at a pillar far from the exit ... and retreats gradually to the exit. If robbing did not take place, all the pillar coal will be lost forever. |

As mines became more sophisticated and industrial technology

advanced,

underground furnaces were replaced by a single gigantic fan powered by its own steam engine.

underground furnaces were replaced by a single gigantic fan powered by its own steam engine.

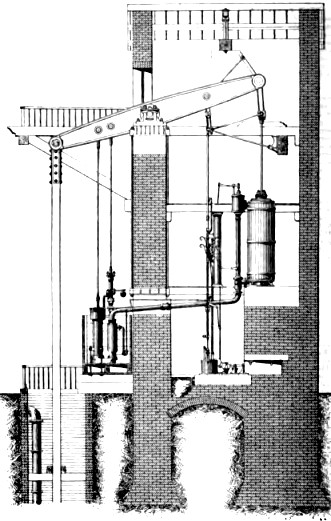

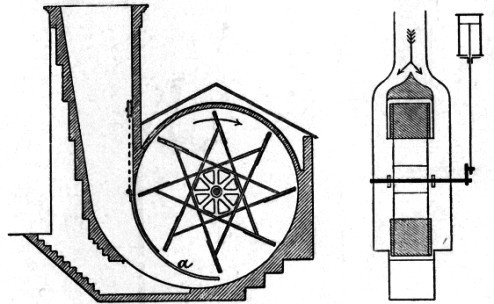

A Guibal fan from the late 1800s.

Left, vertical cross-section seen from the side;

Right, horizontal cross-section seen from above.

LEFT: Most of the components could be made locally. A brick enclosure held the impeller which ran at a constant speed.

The aperture at 'a' would be opened to increase the volume of air exhausted from the mine.

RIGHT: A steam cylinder powers the driving shaft. Air from the mine flows in around the impeller.

The paddles drive the air up the exhaust ... the white square at the bottom.

Usually a second fan system was maintained as backup.

Fans working on the upcast section of the shaft to suck fresh air through the mine were usually thought to be better because they were more likely to continue functioning if there was an explosion in the mine ... that is ... their vanes were turning the same direction as the explosion overpressure and were less likely to be damaged.

As well, under normal conditions, it was thought that the air course would not experience resistant 'back pressure' at locations where air was being forced through a constricted space.

Most importantly, rather than working through the passive convection of rarefied hot air from a furnace ... steam powered fans could quickly increase power to purge mines of explosive or suffocating gases in emergencies.

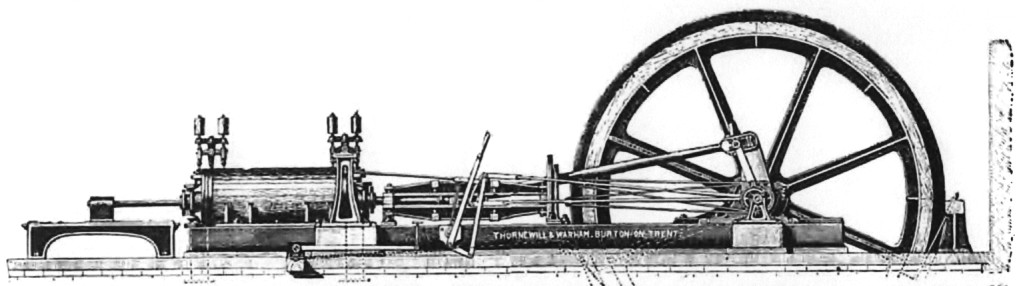

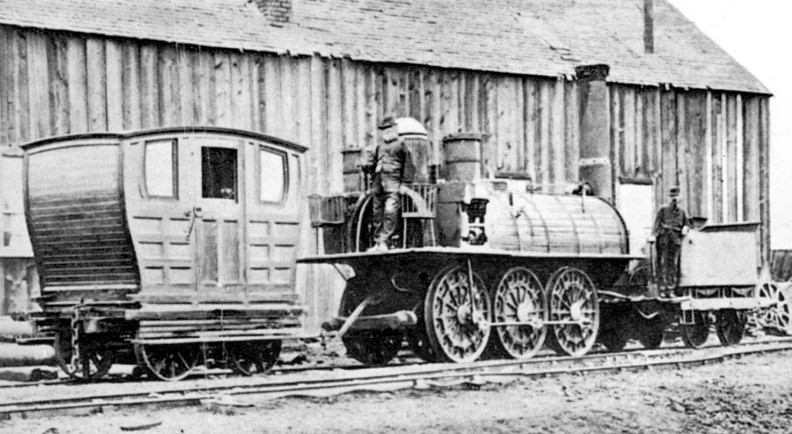

The 'Samson' in Nova Scotia.

The man between the chairs may have been George Davidson - the Scottish engineer

sent to Canada to assemble and manage the steam equipment at this location.

Albion (now known as Stellarton)

Nova Scotia was the site of the General Mining Association's coal

mining operations. Beginning in 1829, horses were used on a light

railway to draw coal cars out of the mines and to the wharf near

Pictou. The GMA had a legal monopoly which was significant in later

history as Nova Scotia and Canada became locally governed and sought local control over resources within their boundaries.

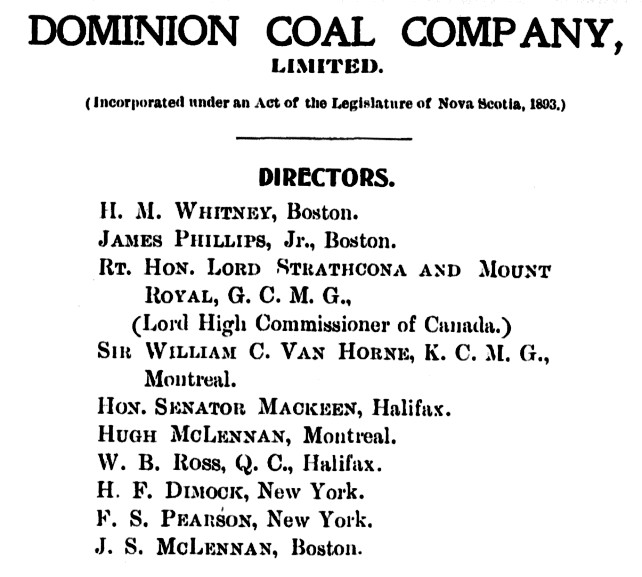

King George IV's brother - the Duke of York - was granted the mineral rights to Nova Scotia and Cape Breton. The Duke immediately paid a jeweller's debt with them and the rights were subsequently purchased by a group of London investors ... naming themselves the GMA.

Being a British syndicate, the GMA imported modern industrial technology in the form of the locomotive 'Samson' and two others. They were shipped from the coal centre Newcastle, England in 1838. The powerful ... for their time ... locomotives could pull about 100 tons, and weighed about 20 tons themselves. You'll notice the unusual design - compared to more recent locomotives ... the engineer and pistons are at one end ... and the firemen stokes from the opposite end below the smokestack. I have always wondered if the 'ergonomic' seats for the engineer were securely anchored. Today the locomotive 'Samson' is preserved at Stellarton.

Smelting iron from the nearby mine, 3 foot cast iron 'fish belly' rails were made for the railway ... some wavy fish belly rails can be seen in the centre foreground.

We may think of modern railways as intercity 'common carriers' moving anything or anyone who wants to travel. Back in the Samson era, the coal mining industry of Britain was a major employer of short private horse tramways and steam powered railways to get coal from the mines to the nearest water transportation. This pattern was also common around Nova Scotia's coal and iron operations. Passenger transportation, in the form of stage coach bodies mounted on flanged wheels, was an afterthought.

To pay a bill:

King George IV's brother - the Duke of York - was granted the mineral rights to Nova Scotia and Cape Breton. The Duke immediately paid a jeweller's debt with them and the rights were subsequently purchased by a group of London investors ... naming themselves the GMA.

Being a British syndicate, the GMA imported modern industrial technology in the form of the locomotive 'Samson' and two others. They were shipped from the coal centre Newcastle, England in 1838. The powerful ... for their time ... locomotives could pull about 100 tons, and weighed about 20 tons themselves. You'll notice the unusual design - compared to more recent locomotives ... the engineer and pistons are at one end ... and the firemen stokes from the opposite end below the smokestack. I have always wondered if the 'ergonomic' seats for the engineer were securely anchored. Today the locomotive 'Samson' is preserved at Stellarton.

Smelting iron from the nearby mine, 3 foot cast iron 'fish belly' rails were made for the railway ... some wavy fish belly rails can be seen in the centre foreground.

We may think of modern railways as intercity 'common carriers' moving anything or anyone who wants to travel. Back in the Samson era, the coal mining industry of Britain was a major employer of short private horse tramways and steam powered railways to get coal from the mines to the nearest water transportation. This pattern was also common around Nova Scotia's coal and iron operations. Passenger transportation, in the form of stage coach bodies mounted on flanged wheels, was an afterthought.

George Monro Grant describes Cape Breton in 1882